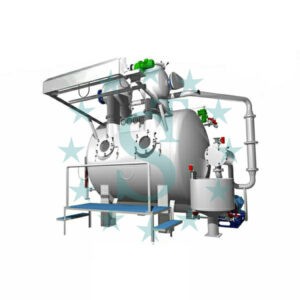

Multi-Nozzle Soft flow

Multi-Nozzle Soft Flow is a Low/High-Temperature dyeing machine technology that works as a “Soft flow” or as a “Jet dyeing” machine.

The main advantage of this development is to increase the machine’s flexibility and versatility to process all types of fabrics.

The soft nozzles in this new technological advancement have a large diameter, and the fixed nozzle has an individual flow control valve, whereas the main nozzle is adjustable.

By increasing and decreasing the gap of a nozzle, flow and pressure increase or decrease as per fabric quality demand.

To run Multi-Nozzle Soft Flow as a soft flow machine, increase the gap Which, subsequently decreases the pressure and increases water flow,

At the time, all three nozzles worked as Soft flow & water flow gets controlled individually by the control valve As per fabric quality demand.

To run The Multi-Nozzle Soft Flow as a “Jet dyeing” Machine lowering the gap of a nozzle which increases the pressure and decreases the water flow. That time close the soft-nozzle control valve.

🔸 Technical Specification

✅ Capacity: 25 to 400 kg. (Single Tube)

✅ Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye –30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ Max. Fabric Speed – 400 Mtr./Min.

✅ Work as a Jet Dyeing or as Soft flow to meet the requirements of all types of fabric quality.

✅ Vessel: SS 316 L.

✅ Multiple soft nozzles.

₹951,000.00

CompareMulti-Nozzle Soft flow

Multi-Nozzle Soft Flow is a Low/High-Temperature dyeing technology that works as a “Soft flow” or as a “Jet dyeing” machine.

The main advantage of this development is to increase the machine’s flexibility and versatility to process all types of fabrics.

The soft nozzles in this new technological advancement have a large diameter, and the fixed nozzle has an individual flow control valve, whereas the main nozzle is adjustable.

By increasing and decreasing the gap of a nozzle, flow and pressure increase or decrease as per fabric quality demand.

To run Multi-Nozzle Soft Flow as a soft flow machine, increase the gap Which, subsequently decreases the pressure and increases water flow,

At the time, all three nozzles worked as Soft flow & water flow gets controlled individually by the control valve As per fabric quality demand.

To run The Multi-Nozzle Soft Flow as a “Jet dyeing” Machine lowering the gap of a nozzle by which increases the pressure and decreases the water flow. That time close the soft-nozzle control valve.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg. (Single Tube)

✅ Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye –30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ Max. Fabric Speed – 400 Mtr./Min.

✅ Work as a Jet Dyeing or as Soft flow to meet the requirements of all types of fabric quality.

✅ Vessel: SS 316 L.

✅

🔸 Payment, Taxes and Delivery

Payment: 40% Advance online & Balance against Proforma Invoice prior to dispatch.

Delivery: Delivery of machine is ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above given price.

| Capacity | 25Kg, 50Kg, 75Kg, 100Kg, 150Kg, 200Kg, 250Kg, 300Kg, 400 Kg |

|---|---|

| Nossel size | 105mm, 120mm, 140mm, 200mm, 250mm, 300mm |

| Fabric | WOVEN, KNITTED, WOVEN & KNITTED |

Based on 0 reviews

Be the first to review “Multi-Nozzle Soft flow”

-

Burner, Heating Solution

Burner 200 – Stage 2

Burner 200 | Heating solution

The Gas Burner 200 is a heating solution for small-medium appliances. The gas burner can be used as either a primary or secondary heating source, offering great versatility to users. It is designed not only to be functional but also beautiful.

We designed this, will ensure you have a high-efficiency, energy-efficient heating solution.

The gas burner was created as a way of providing an aesthetically pleasing solution for companies looking for a simpler alternative.

Benefits

✅ Modern design

✅ Efficient

✅ Aesthetic

✅ Environmentally friendly

✅ Reduces air pollution because it reduces wood consumption by up to 5 times

✅ Tangential Ventilation

✅ Heats quickly and efficiently

SKU: n/a -

Processing Machinery

Chainless Merceriser

Chainless Merceriser

The Chainless Merceriser is the most Significant procedure for the cloth. Chainless Merceriser machine there are following features in it.

- To begin with, Chainless Merceriser is one of the most fundamental steps for finishing cotton fabrics. Merceriser involves treating organic material with high-caustic soda solutions. In other words, it eliminates impurities or undesired particles from the cloth before completing other processes.

- Secondly, It rolls cloth on batching trolley from fold/loose form by pressure roll assisted with twin – Pneumatic Cylinders, AC Motor & Gearbox.

- Thirdly, The caustic soda-impregnated Fiber reflects light, making it brighter. It also boosts hygroscopicity, strength, and dye affinity.

- Fourthly, The operating width of a chainless merceriser can range from 1500mm to 3500 mm, as preferred by the customer.

- Fifthly, It can process woven fabrics with capacities ranging from 70 to 700 grammes per square metre.

- Lastly, It is available in various sizes and speeds ranging from 8 to 40 metres per minute.

In conclusion, this merceriser machine is best suitable for the garment industry Dyeing & printing plants.

🔸 ADVANTAGES :

➡ Increase dye Affinity

➡ Improve Luster

➡ Add more Tensile Strength

➡ Increase Dimensional Stability of Warp & Weft yarn.

➡ Elimination of immature or Dead Cotton

➡ Improved Handling effects.

➡ Tailored to the customer’s specifications.

SKU: P/CM-1 -

Dyeing Machinery

Regular Jet

Regular Jet dyeing

This machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside this polyester dyeing machine moves solely due to the force of water.

It is user-friendly because, If we compare it with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 LBest Polyester dyeing machine with a low liquor ratio in a Jet dyeing form.

SKU: D/JD-1 -

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 -

Finishing Machinery

Stenter

The Stenter or Hot air Stenter Machine is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities give the fabric the final result of all the processes it went through.

Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out.

It also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.🔶 Efficiency

✅ Double-jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advanced chamber technology makes it easy to install and reinstall if needed without interfering with the performance.Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

SKU: S001 -

Washing Machinery

Rope Washing Range

Rope Washing Range

Rope Washing Range is a fabric washing machine. Therefore, The Rope Washing Range is for woven fabrics like cotton, cotton/viscose, cotton/polyester or linen and knitted fabrics.

Viscose washed in rope form because of its poor wet strength.

Similarly, Knit fabrics tend to elongate in open form and require many holding gadgets. So, it is washed in rope form to avoid curling and elongation.

The Rope Washing Rang has two open-width compartments/triple drum compartment/cage washer for wetting and swelling dyes as well gum paste, fabric then gathered in a J-scray before going into the winch washing compartments.

The oval-type S.S. winch helps in thrashing the cloth into the S.S. washing tank to remove the gum and excessive colour.

There is a provision for heating the water with steam for faster removal of excessive materials. Long dwell times, controlled temperature and liquor flow to suit individual requirements add high washing efficiency.

Each tank can hold 110 kilos to 200 kilogrammes of cloth, depending on the breadth of the tank. After being washed with a rope opening mechanism, the fabric takes on an open state.

🔶 ADVANTAGES :

✅ Excellent washing efficiency.

✅ Sturdy construction.

✅ Low energy consumption.

✅ Quiet running.

✅ Lowest maintenance effort.

✅ Speed up to 70 Meters / Min.

✅ Easy installation

SKU: n/a

There are no reviews yet.