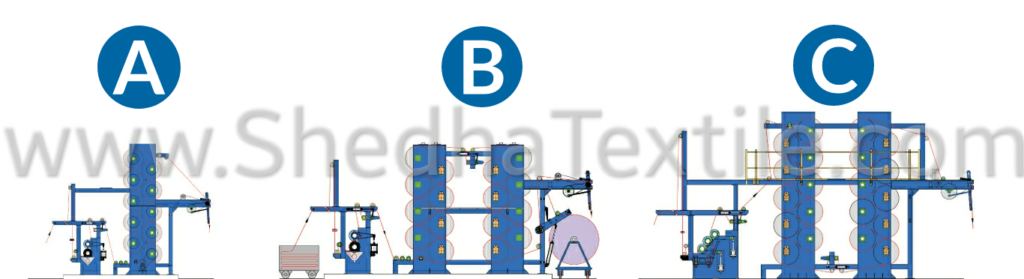

Semi Automatic Jigger Machine

Semi Automatic Dyeing Jigger

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width

Semi Automatic Jumbo Jigger Machine

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width

₹325,000.00

CompareSemi Automatic Dyeing Jigger

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width

Semi Automatic Jumbo Jigger Machine

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width

| Semi Automatic | Dyeing Jigger Machine, Jumbo Jigger Machine |

|---|

Based on 0 reviews

Be the first to review “Semi Automatic Jigger Machine”

-

Washing Machinery

Open Width Washing Range

Open width Washing Range

Open width Washing Range is for the fabric washing machine for woven fabrics. The Open width Washing Range machine has the following features.

- Firstly, The system consists of a specially shaped impeller in the drum in which water jets uniformly smashes the full fabric width very high washing performance on the upper and backside of the fabric.

- In other words, Open width Washing Range removes unfixed dyestuff, gum, and other chemicals from the fabric.

- Secondly, Washing with tanks can carry out pre-washing, rinsing, and chemical treatment.

- Therefore, Open width Washing Range improves fabric quality.

- An effective squeezer between the washing unit gives maximum liquor separation from one bath to another.

- Thirdly, Each washing compartment with its force-spray system, re-circulation pump, filtering device, overflow, drain, and heating arrangement.

- Fourthly, the Open width Washing Range’s working width is to be made from 1500mm to 3500mm depending on the client’s need.

- Fifthly, ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabric can be processed on this machine.

- Sixth and most Important is Perfect synchronizing of linear speed hence tension-less and creaseless transport of fabric all along the process.

🔶 ADVANTAGES :

✅ Excellent Washing efficiency.

✅ Extremely sturdy construction.

✅ Quiet running.

✅ Low energy consumption.

✅ Ease of operation.

✅ Optional knife spray between each strand of fabric with supply from a separate pump.

✅ Circulation and counter flow arrangement to save water.

✅ Low maintenance.

✅ Quick and simple installation.

✅ Tight closing glass windows on the sides to provide easy access.

✅ Direct steam heating by perforated S S Pipes.

✅ S S bottom rolls running in self-aligning bush bearing.

SKU: n/a -

Batching, Makeup Machinery

Wider-width Single Folding

Wider-width Single folding machine is to fold/measure the length of fabric before process and also to measure it after the final process.

Fabric ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester. this type of machine works in units which dye, print or process wider width fabric such as curtains, blankets and bedsheets cause most of these type of products has wider width. Length of folds can be adjustable up to 1 meter with table descends up to 380mm.

It comes in four different sizes from 84″/79 (Small)* to 120″/115 (Large)SKU: n/a -

Dyeing Machinery

Multi-Nozzle Soft flow

Multi-Nozzle Soft Flow is a Low/High-Temperature dyeing machine technology that works as a “Soft flow” or as a “Jet dyeing” machine.

The main advantage of this development is to increase the machine’s flexibility and versatility to process all types of fabrics.

The soft nozzles in this new technological advancement have a large diameter, and the fixed nozzle has an individual flow control valve, whereas the main nozzle is adjustable.

By increasing and decreasing the gap of a nozzle, flow and pressure increase or decrease as per fabric quality demand.

To run Multi-Nozzle Soft Flow as a soft flow machine, increase the gap Which, subsequently decreases the pressure and increases water flow,

At the time, all three nozzles worked as Soft flow & water flow gets controlled individually by the control valve As per fabric quality demand.

To run The Multi-Nozzle Soft Flow as a “Jet dyeing” Machine lowering the gap of a nozzle which increases the pressure and decreases the water flow. That time close the soft-nozzle control valve.

🔸 Technical Specification

✅ Capacity: 25 to 400 kg. (Single Tube)

✅ Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye –30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ Max. Fabric Speed – 400 Mtr./Min.

✅ Work as a Jet Dyeing or as Soft flow to meet the requirements of all types of fabric quality.

✅ Vessel: SS 316 L.

✅ Multiple soft nozzles.

SKU: D/MSF-1 -

Processing Machinery

Polymeriser

Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.

SKU: P001 -

Dyeing Machinery

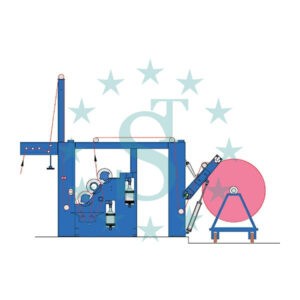

CP Dyeing

CP Dyeing

CP Dyeing is dyeing machinery to Dye Fabrics rapidly. Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.

SKU: n/a

There are no reviews yet.