Accessories

Showing all 3 results

-

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 -

Accessories

Roll Wrapping

Roll Wrapping

Fabric Roll wrapping machine is one of the most required Accessories for pre-delivery processes in Textile plants and Mills. The primary object of the fabric roll wrapping machine is to wrap ready-to-ship rolls so that the fabric remains safe while being delivered to the customer.

Fabric Roll wrapping machines can wrap material rolls of Denim Cloth, Curtain Cloth, Carpets, Foam sheets, Upholsteries, Fabrics, Film, Paper etc. which have a Maximum roller height from ground level up to 400 millimetres.

The fabric Roll wrapping machine is simple to operate, and the sturdy & safe control panel makes it easy to load and unload the fabric roll with the ease of integration into conveyor lines.

With a speed of up to 50 meters per minute, making 20 to 40 rolls per hour while performing variable overlap, amount of stretch, and roller speed, the fabric roll wrapping machine saves labour, time and money.

Because of its unique construction, traverse can accommodate a variety of roll widths. Maximum stretch Power Roller Pre-Stretch Carriage with Pre-Stretch Ratio adjustable up to 300% (Depending upon Film Gauge & Quality).

Inshot fabric Roll wrapping/Stretch wrap machines make it possible to wrap, store and protect ready-to-ship rolls while protecting rolls from dirt and damage.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ Maximum roller height from ground level up to 400mm can be processed.

✅ Speed up to 50 meters/minute.

✅ Maximum stretch Power Roller Pre-Stretch Carriage with Pre-Stretch Ratio adjustable up to 300% (Depending upon Film Gauge & Quality).

✅ Rolls/Hour: 20-40 rolls.

✅ Weight/Roll: 400kgs

✅ Roll Diameter: 600mm

✅ Roll Width: 2100mm (As Par Fabric width)

SKU: A/WR-1-1 -

Accessories

Rubber Blanket

Rubber Blanket

in the textile finishing process for pre-shrinking fine, lightweight cloth, Twills, Drills, & other medium-weight fabrics. Rubber Blanket has the following features:

- Firstly, the Rubber Blanket is produced from the highest quality, dirt-free natural rubber and selective quality polymers to give extremely high compressive strength to the product.

- Secondly, it ensures a non-stick surface for excellent fabric finish during the shrinkage process of textile.

- Thirdly, the high-quality speciality rubber additive with high-performance anti-degradants is selected to prevent surface degradation of the Rubber Blanket at high-temperature processing, which gives excellent heat resistance and superior flex life to the product.

- Fourthly, a Superior quality Rubber blanket can effortlessly process at high steam pressure on modern high-speed machines to give shrinkage-free fabrics. Because of the heat resistance nature of the Rubber Blanket, it Gives uninterrupted service before stopping the machine from grinding the new smooth surface.

- Fifthly, The good abrasive surface and excellent flex quality of the Rubber Blanket are Expected to give at least 10 to 15% higher meterage of fabric under ideal processing conditions than other brands of Rubber Banket available in the Indian market.

Moreover, Producers of lightweight, low shrinkage potential, 100% cotton or cotton/polyester, commonly report from 15 million to 20 million meters of productive life.

🔶 Technical Specification

- Hardness: The recommended hardness of a Rubber Blanket is between 36 degrees to 39 degrees depending on the fabrics to be processed.

- Fabric Width: offer current width of 1200mm to 3500mm.

- Usually, Rubber Banket should be 150 mm to 200 mm wider than FELT the cloth to be processed.

- Pressure Circumference: The standard internal circumference of the Rubber Blanket is 3962mm (13 feet)

- Thickness: The most common thickness of a Rubber Blanket is 67 mm (2.5/8″) and varies up to 70mm. The higher thickness will initially require higher force for outer surface elongation as the Blanket turns around the pressure. Results in cracks on the outer surface & will need to grind the surface frequently and often rubbing the Rubber Blanket from the inner surface. Usually, Rubber Blanket thickness depends on the required shrinkage in fabrics.

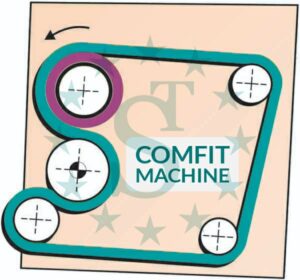

- The Rubber Blanket has a maximum shrinkage capacity of Up to 15% for lightweight fabric processed on a comfit type machine 50 mm.

- Usually, Rubber Belt thickness depends on the shrinkage needed in fabrics. For lightweight processed fabrics with low shrinkage fabrics such as poplins, fancy prints & synthetics dress material etc., a Belt thickness of 55 mm is required. This rubber belt will have a shrinkage capacity of 5-8% for processing heavy weight fabrics like Denim, Twill, Drills etc. thickness Belt of 67-71 mm is needed. The Rubber Belt has a maximum shrinkage capacity of Up to 15% for lightweight fabrics processed on a comfit type machine 50 mm A thick belt is most suitable with 3-5% shrinkage.

In conclusion, Rubber Blanket is best suitable for the garment industry or dyeing & printing plants which use the machines like Compressive Shrinking Range or Zero Zero & Comfit.

SKU: n/a