Burner 200 – Stage 2

Burner 200 | Heating solution

The Gas Burner 200 is a heating solution for small-medium appliances. The gas burner can be used as either a primary or secondary heating source, offering great versatility to users. It is designed not only to be functional but also beautiful.

We designed this, will ensure you have a high-efficiency, energy-efficient heating solution.

The gas burner was created as a way of providing an aesthetically pleasing solution for companies looking for a simpler alternative.

Benefits

✅ Modern design

✅ Efficient

✅ Aesthetic

✅ Environmentally friendly

✅ Reduces air pollution because it reduces wood consumption by up to 5 times

✅ Tangential Ventilation

✅ Heats quickly and efficiently

₹75,000.00

CompareThe Gas Burner 200 is a heating solution for small-medium appliances. The burner can be used as either a primary or secondary heating source, offering great versatility to users. It designed not only to be functional but also beautiful. We designed this gas burner, which will ensure you have a high-efficiency, energy efficient heating solution.

The gas burner was created as a way of providing an aesthetically pleasing solution for companies looking for a simpler alternative.

Benefits

✅ Modern design

✅ Efficient

✅ Aesthetic

✅ Environmentally friendly

✅ Reduces air pollution because it reduces wood consumption by up to 5 times

✅ Tangential Ventilation

✅ Heats quickly and efficiently

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

| Max Capacity | 120kW, 140kW, 200kW |

|---|

Based on 0 reviews

Be the first to review “Burner 200 – Stage 2”

-

Processing Machinery

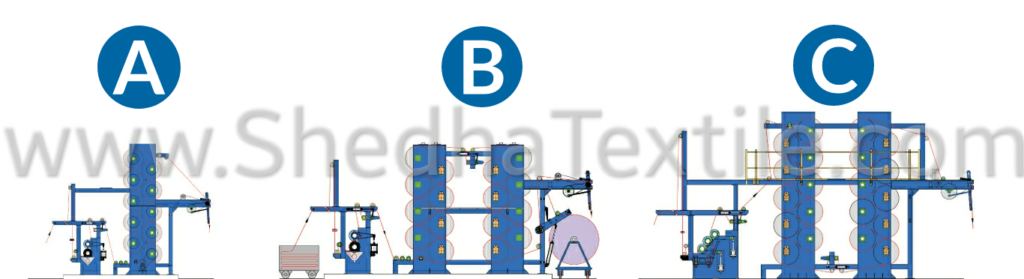

Polymeriser

Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.

SKU: P001 -

Batching, Makeup Machinery

Single Folding Machine

This Single Folding machine or fabric folding machine is one of the fabric makeup machinery which has the following features :

- Firstly, the Single Folding machine does fold the fabric from a loose form to an organized plated state before performing dyeing/printing/processing operations.

- In other words, the fabric needs an inspection before starting any processes.

- Secondly, the Single Folding machine also measures fabric length before any operation or after all processes.

- Thirdly, the Single Folding machine comes in four different sizes from 41″/36 (Small)* to 72″/67 (Large)

- Fourthly, woven fabrics like cotton, viscose, rayon, wool & polyester weigh from 70 to 700 gsm/meter square and fold on a Single Folding machine.

- Fifth and most importantly, the speed can be achieved up to 50 meters per minute while performing the process.

In conclusion, this fabric folding machine is best suitable for the garment industry or dyeing & printing plants.

🔸 Technical Specification

✅ For fabric up to 1700MM

✅ The working table descends up to 15” (380 mm).

✅ Length is of folds adjustable up to 1.00 meter.

✅ Cast Iron sidewalls are closed to make the machine robust and sturdy.

✅ Folding blades mounted on the carriage of steel roller chains.

✅ a simple device for quick and precise folding with knife adjustment

✅ Operating speed: 50 meters/minute.

✅ Drive on motor 2HP x 960RPM.

✅ Stroke-type length Counter with manual setting or ⭕ Digital counter.

SKU: n/a -

Dyeing Machinery

Jigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

SKU: jigger -

Dyeing Machinery

CP Dyeing

CP Dyeing

CP Dyeing is dyeing machinery to Dye Fabrics rapidly. Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.

SKU: n/a -

Boiler, Heating Solution

Gas Boiler

GAS Boiler

The Gas Boiler is a packaged three-pass smoke tube with a total wet back boiler. Gas Boiler comes in two three series for burning light oils & gas and heavy oils.

The Gas Boiler also can be customized to a complete skid mount unit on customer demand.

When fitted with a particular burner, these boilers are ideal for burning waste gases like biogas from the decomposition of organic matter in distilleries.

🔸 PRODUCTS FEATURES:

✅ Three-pass smoke tube with complete wet back boiler.

⭕ Multi-fuel option – light oils/heavy oils/gases

✅ High efficiency of about 88% to 95%

✅ High dryness fraction steam increases usable heat.

✅ Gas Boiler Comes with mono-block/ dual block/steam atomized burner with world-renowned Technology from (ITALY)

⭕ An additional option of oil pre-heater confirming EN safety standards

✅Corrugated furnaces for boilers above 6 TPH capacity.

⭕ Optional PLC-based control panels that would be linked to SCADA or DCS systems.🔸 Operating Range:

➡ Capacities In the range of 1.0 TPH to 15 TPH

➡ Pressure: In the range of 10.54 to 17.54 Kg/cm2 (g)

➡ Firing fuels: LDO, FO, LSHS & Natural Gas

➡ Efficiency: Overall efficiency of 88 % (+/-2%) on NCV

SKU: H/GB-1

There are no reviews yet.