Burner 550 – Stage 3

Burner 550 | Heating solution

This heating solution burner 550 comes to volume, potential, and cost efficiency. The Burner 550 is a series stage 3 covers output ranges under 80mg/kWh. These gas burners were designed with an advanced combusting head which provides consistent combustion even under difficult working conditions.

The placement of the components inside the burner permits easy and precise regulation and maintenance.

Benefits

🔥 Amazingly efficient at burning gas

🔥 Stable flame no matter what kind of weather you’re dealing with

🔥 High efficiency (80mg/kWh)

🔥 Efficient, clean combustion

🔥 Power is increased without complications

✅ Easy to maintain

✅ Great energy savings

₹95,000.00

CompareThis heating solution burner 550 comes to volume, potential, and cost efficiency. The Burner 550 is a series stage 3 covers output ranges under 80mg/kWh. These gas burners were designed with an advanced combusting head which provides consistent combustion even under difficult working conditions.

The placement of the components inside the burner permits easy and precise regulation and maintenance.

Benefits

🔥 Amazingly efficient at burning gas

🔥 Stable flame no matter what kind of weather you’re dealing with

🔥 High efficiency (80mg/Kwh)

🔥 Efficient, clean combustion

🔥 Power is increased without complications

✅ Easy to maintain

✅ Great energy savings

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

| Max Capacity | 280kW, 350kW, 400kW, 550kW |

|---|

Based on 0 reviews

Be the first to review “Burner 550 – Stage 3”

-

Accessories

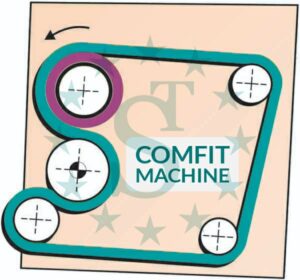

Rubber Blanket

Rubber Blanket

in the textile finishing process for pre-shrinking fine, lightweight cloth, Twills, Drills, & other medium-weight fabrics. Rubber Blanket has the following features:

- Firstly, the Rubber Blanket is produced from the highest quality, dirt-free natural rubber and selective quality polymers to give extremely high compressive strength to the product.

- Secondly, it ensures a non-stick surface for excellent fabric finish during the shrinkage process of textile.

- Thirdly, the high-quality speciality rubber additive with high-performance anti-degradants is selected to prevent surface degradation of the Rubber Blanket at high-temperature processing, which gives excellent heat resistance and superior flex life to the product.

- Fourthly, a Superior quality Rubber blanket can effortlessly process at high steam pressure on modern high-speed machines to give shrinkage-free fabrics. Because of the heat resistance nature of the Rubber Blanket, it Gives uninterrupted service before stopping the machine from grinding the new smooth surface.

- Fifthly, The good abrasive surface and excellent flex quality of the Rubber Blanket are Expected to give at least 10 to 15% higher meterage of fabric under ideal processing conditions than other brands of Rubber Banket available in the Indian market.

Moreover, Producers of lightweight, low shrinkage potential, 100% cotton or cotton/polyester, commonly report from 15 million to 20 million meters of productive life.

🔶 Technical Specification

- Hardness: The recommended hardness of a Rubber Blanket is between 36 degrees to 39 degrees depending on the fabrics to be processed.

- Fabric Width: offer current width of 1200mm to 3500mm.

- Usually, Rubber Banket should be 150 mm to 200 mm wider than FELT the cloth to be processed.

- Pressure Circumference: The standard internal circumference of the Rubber Blanket is 3962mm (13 feet)

- Thickness: The most common thickness of a Rubber Blanket is 67 mm (2.5/8″) and varies up to 70mm. The higher thickness will initially require higher force for outer surface elongation as the Blanket turns around the pressure. Results in cracks on the outer surface & will need to grind the surface frequently and often rubbing the Rubber Blanket from the inner surface. Usually, Rubber Blanket thickness depends on the required shrinkage in fabrics.

- The Rubber Blanket has a maximum shrinkage capacity of Up to 15% for lightweight fabric processed on a comfit type machine 50 mm.

- Usually, Rubber Belt thickness depends on the shrinkage needed in fabrics. For lightweight processed fabrics with low shrinkage fabrics such as poplins, fancy prints & synthetics dress material etc., a Belt thickness of 55 mm is required. This rubber belt will have a shrinkage capacity of 5-8% for processing heavy weight fabrics like Denim, Twill, Drills etc. thickness Belt of 67-71 mm is needed. The Rubber Belt has a maximum shrinkage capacity of Up to 15% for lightweight fabrics processed on a comfit type machine 50 mm A thick belt is most suitable with 3-5% shrinkage.

In conclusion, Rubber Blanket is best suitable for the garment industry or dyeing & printing plants which use the machines like Compressive Shrinking Range or Zero Zero & Comfit.

SKU: n/a -

Dyeing Machinery

Jigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

SKU: jigger -

Processing Machinery

Polymeriser

Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.

SKU: P001 -

Finishing Machinery

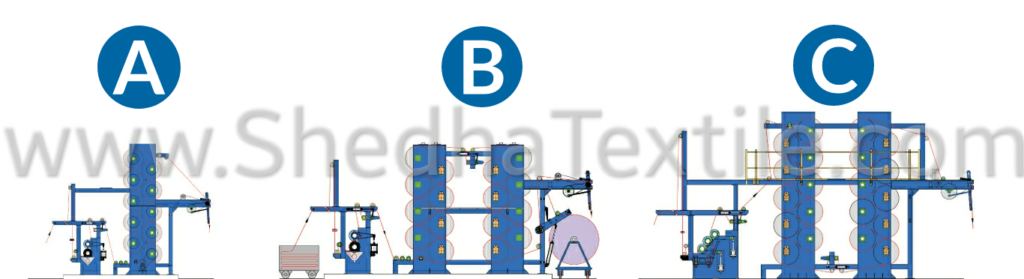

Compressive Shrinking Range

The Sole purpose of the Controlled Compressive Shrinking Range or ZEROZERO is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Controlled Compressive Shrinking Range or ZEROZERO are available up to 3200mm working width fabric to assure total shrinkage protection to woven fabrics. It can be 100% cotton, cotton/polyester, cotton/viscose or tough and heaviest fabric like denim. Compressive Shrinking Range or ZEROZERO developed in a way that can shrinkage up to 12% in a single passage.

The most capable of shrinking medium, lightweight fabric to the heaviest denim, cotton blended suiting & shirting by watering cotton, terylene, hemp and its blends to shrink the cloth to meet the requirements of shrinkage, stabilization and improve the hand touch.

A controlled Compressive Shrinking Range is usually the last process in the sequence of fabric finishing. The woven fabric processed in the machine gets fully shrunk.

Before compressive shrinking, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Technical Specification

✅ A.C. frequency conversion transmission, designed speed: 10-80m/minute.

✅ Shrinkage 0 – 12 % depending upon fabric quality.

✅ Minimum and controlled tension.

⭕ Imported Rubber Blanket and Polyester Felt will be provided optionally.

✅ A Jacketed drum in 1500mm, 2000mm and 2500mm diameters.

✅ Stainless Steel damping & conditioning unit supplied as standard Parts.

SKU: n/a -

Dyeing Machinery

Automatic Jigger

Automatic JIGGER is one of the best dyeing machine inventions for simplifying the dying process. Automatic JIGGER is a Hybrid of hydraulic & conventional JIGGER.

Automatic JIGGER comes with two types 1st one is OPEN TYPE & other one is CLOSE TYPE.

Where One-hand OPEN TYPE Automatic JIGGER comes with all the benefits like

✅ Auto tension control

✅ Auto speed control

✅ Auto cycle control

✅ Circulation system with filters to avoid centre to selvedge

✅ Suitable for any exhaust pre-treatment, dyeing & finish process

✅ Tension setting device to avoid running crease & machine jerks

⭕ Auto pendulum control (optional)

⭕ Batching or winch device (optional)

⭕ Auto water level controller (optional)

⭕ Pneumatic operated drain (optional)Otherhand CLOSE TYPE Automatic JIGGER comes with the additional features like

✅ Auto circulation system

✅ Auto temperature controller

✅ A fully covered jigger will save utilities

⭕ Dosing side tank facility (optional)

⭕ Circulation system with filters to avoid centre to narrow border (optional)The tension control system allows Automatic JIGGER to dye any fabric with ease. One operator can run four Automatic JIGGER machines simultaneously thanks to its PLC system, and the individual drive “automatic dyeing jigger” runs on zero tension on the fabric.

Automatic JIGGER uses both rollers powered by separate gearboxes and motors on inverter drives which do wonders for uniform dyes, even when running at varying speeds.

In conclusion, it is the best-woven dyeing machine, fabric dyeing machine or Cotton dyeing machine.

🔶 Technical Specification

✅ Capacity: 300 Kg. to 2000 kg. [OPEN]

✅ Capacity: 500 Kg. to 2000 kg. [CLOSE]

✅ Available Width: 1250mm to 3400mm

✅ S.S. Structure 304 Out Outer body 316 mail rolls plus inner bottom

✅ 0 to 10 Kgs. (Tension less operation Possible)

✅ Suitable for any Fabric from 30gsm to 500gsm

✅ S.S. Cladded Main Roll

✅ Pneumatic cylinders operated doors [CLOSE]

✅ Individual drive on each roller

✅Speed & tension control through a drive

SKU: n/a

There are no reviews yet.