No products in the cart.

Dyeing Machinery

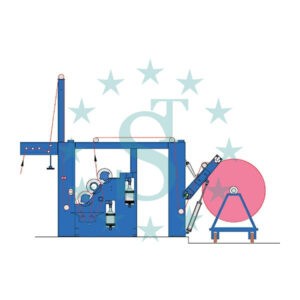

Long Tube Jet

Long tube Jet dyeing machine working concept is same compare with Convention Rapid long tube jet dyeing machine. Though the major advantage of this machine is liquor ration is nearly half than conventional rapid Jet dyeing machine. In this machine fabric does not float but it run nearly in dry condition. Another benefit of this machine is it’s single vessel with two chamber design. Due to this design fabric loop length is reduce additionally bringing down the running cost, capital cost as well as processing time.

[spbsm-follow-buttons]

₹1,800,000.00

Long Tube Jet

Long tube Jet dyeing machine working concept is same compare with Convention Rapid long tube jet dyeing machine. Though the major advantage of this machine is liquor ration is nearly half than conventional rapid Jet dyeing machine. In this machine fabric does not float but it run nearly in dry condition.

Another benefit of this machine is it’s single vessel with two chamber design. Due to this design fabric loop length is reduce additionally bringing down the running cost, capital cost as well as processing time.

Technical Specification

- Capacity : 250 to 400Kg.

- Dye – 30 To 450 Grams/Meter. Sq. Fabrics (Woven & Knitted Fabrics)

- Low Liquor ratio: 1:3 to 1:4 (Wet fabric)

- High Temp. – Up to 140 ° C.

- Vessel made from – SS 316 L

- Single Vessel two chamber to reduce the loop length as well as process time.

- Inside PTFE Teflon sheet for entangle operation.

- Online washing system.

- Specially design bow jet nozzle for extra force.

- Fabric drive reel with frequency controller.

Payment, Taxes and Delivery

Payment: 40% Advance & Balance against Proforma Invoice prior to dispatch.

Delivery: Delivery of machine is ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( Export Orders).

Erection: Will be charged extra per machine over and above given price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

| Capacity | 250 Kgs, 300 Kgs, 400 Kgs |

|---|---|

| Fabric | WOVEN, KNITTED |

Based on 0 reviews

Be the first to review “Long Tube Jet”

- Burner, Heating Solution

Burner 200 – Stage 2

Burner 200 | Heating solution

The Gas Burner 200 is a heating solution for small-medium appliances. The gas burner can be used as either a primary or secondary heating source, offering great versatility to users. It is designed not only to be functional but also beautiful.

We designed this, will ensure you have a high-efficiency, energy-efficient heating solution.

The gas burner was created as a way of providing an aesthetically pleasing solution for companies looking for a simpler alternative.

Benefits

✅ Modern design

✅ Efficient

✅ Aesthetic

✅ Environmentally friendly

✅ Reduces air pollution because it reduces wood consumption by up to 5 times

✅ Tangential Ventilation

✅ Heats quickly and efficiently

SKU: n/a - Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 - Dyeing Machinery

Atmospheric Soft Over Flow

Atmospheric Soft flow

The Atmospheric Soft Flow machine is the same as HTHP Soft flow Dyeing machine. The only difference is Atmospheric Soft Flow works at low temperatures & without pressure.

Some fabrics like Cotton & Cotton blends don’t require high temperatures. In that case, Soft Flow is very much suitable because Atmospheric Soft Flow reduces the running cost by saving energy. In short, it is a Cotton dyeing machine.

Furthermore, the liquor ratio of the Soft Flow machine is lower than that of the HTHP Soft Flow machine.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:4 (wet Fabric)

✅ Capacity: 50 to 1200 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ Maximum Temprature – Up to 98° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/ASF-1 - Processing Machinery

Chainless Merceriser

Chainless Merceriser

The Chainless Merceriser is the most Significant procedure for the cloth. Chainless Merceriser machine there are following features in it.

- To begin with, Chainless Merceriser is one of the most fundamental steps for finishing cotton fabrics. Merceriser involves treating organic material with high-caustic soda solutions. In other words, it eliminates impurities or undesired particles from the cloth before completing other processes.

- Secondly, It rolls cloth on batching trolley from fold/loose form by pressure roll assisted with twin – Pneumatic Cylinders, AC Motor & Gearbox.

- Thirdly, The caustic soda-impregnated Fiber reflects light, making it brighter. It also boosts hygroscopicity, strength, and dye affinity.

- Fourthly, The operating width of a chainless merceriser can range from 1500mm to 3500 mm, as preferred by the customer.

- Fifthly, It can process woven fabrics with capacities ranging from 70 to 700 grammes per square metre.

- Lastly, It is available in various sizes and speeds ranging from 8 to 40 metres per minute.

In conclusion, this merceriser machine is best suitable for the garment industry Dyeing & printing plants.

🔸 ADVANTAGES :

➡ Increase dye Affinity

➡ Improve Luster

➡ Add more Tensile Strength

➡ Increase Dimensional Stability of Warp & Weft yarn.

➡ Elimination of immature or Dead Cotton

➡ Improved Handling effects.

➡ Tailored to the customer’s specifications.SKU: P/CM-1 - Dyeing Machinery

Semi Automatic Jigger Machine

Semi Automatic Dyeing Jigger

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller WidthSemi Automatic Jumbo Jigger Machine

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width[spbsm-follow-buttons]

SKU: n/a - Accessories

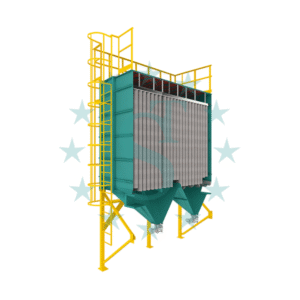

Bag Filter

Bag Filter

A Bag Filter, also known as a dust collector, is a most required Accessory for boiler houses in textile plants and mills. The primary object of the Bag filter is to clean dirty air or gas by trapping dust and particles before the air goes from the chimneys of the Plants and Mills.

The Bag filter consists of multiple woven bags. The bag filter typically holds between 56 and 320 bags, depending on the capacity of the Boiler or Thermopac. These filters effectively capture dust and particles, helping the equipment work efficiently. Their design ensures they fit well with the system while allowing necessary airflow. It has the following features that make it an essential part of Boiler Houses in Textile Plants:

- Firstly, it cleans dirty air and gases by catching them in bags before the air enters the environment.

- Secondly, it helps to contain dirt and pollutants from the air, making the workplace safer for workers and the environment.

- Thirdly, in industries like textiles, even tiny dust particles can affect the quality of the product. Bag filters help maintain a clean environment.

- Fourthly, it is a highly customizable product that can carry between 56 and 320 bags, depending on the capacity of the Boiler or Thermopac.

- Fifth and most importantly, Governments have strict rules on air pollution. Bag filters help companies follow these rules to avoid fines or shutdowns.

Conclusion:

Bag filters are essential for modern industry. They clean the air by removing dust and particles, protecting people and machines. They work efficiently, are built to last, and can be used in different industries, including textile, cement, and food production.

Using bag filters helps industries maintain clean air, comply with environmental laws, and create a safer workplace. They are a wise investment for any company seeking to enhance safety and productivity.

🔸 Technical Specification

✅ Can be customized from 56 to 320 bags.

✅ Attach with Boiler or Thermopac (Thermic Fluid Heater)

✅ From capacity 2 tons to 10 tons (Boiler) & from capacity 500U to 5000U (Thermic Fluid Heater)

SKU: A/BF-1

There are no reviews yet.