No products in the cart.

Processing Machinery

Cylinder Drying Range

Drying Range

The Drying Range or VDR (Vertical Drying Range Machine) is one of the most demanding processing machinery in Woven dyeing & printing plants. The Drying Range has the following features that make it an essential part of the plant.

- Firstly, It ensures rapid drying of fabric at high steam pressure.

- In other words, It is suitable for fabric drying, semi-drying, and fabric that doesn’t require heat setting or Clothes which need semi-dry or completely dry.

- Secondly, a Belt drive or individual drive for tensionless and crease-free passage of fabric on the cylinder result in the cloth moving smoothly.

- Thirdly, an Individual trapping system for faster condensate removal inside chambers.

- Therefore, it keeps cylinders at maximum heat.

- Fourthly, the working width options from 1250mm to 3500mm according to the client’s need.

- Fifthly, ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester can be rolled on this machine.

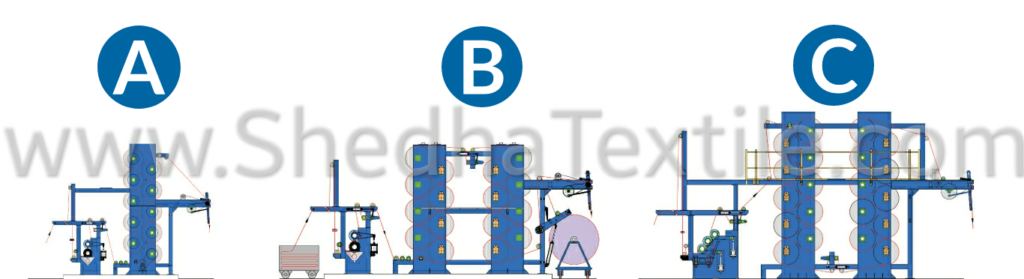

- Sixthly and most Important Drying Range has the option of 6, 8, 10, 12, 16, 20, or 24 cylinders in a single or double frame.

Above all, more numbers of cylinders equal more speed.

In conclusion, this machine is best suitable for Dyeing and Printing Plants.

🔸 Advantages:

➡ Long Lasting & sturdy construction

➡ Lowest consumption data

➡ Quick heating up

➡ Easy to operate

➡ Drying with minimum tension

➡ Crease-free fabric passage

➡ Perfect temperature uniformity across fabric width

➡ Highest product quality

➡ Shut off valves for cylinders

➡ Lowest maintenance effort

➡ Lowest radial run out and perfect welding craftsmanship

🔸 Technical Specification:

✅ Box type or beam stack structures as per choice.

✅ Belt-driven or individual drive for tension-less and crease-free passage for fabric on cylinders.

✅ Options of 2 bowls or three bowls mangle to attached with cylinder dryer as per customer need.

✅ Any width from 1250mm to 3500mm of the dryer is supplied.

✅ The Drying Range has the option of 6, 8, 10, 12, 16, 20, or 24 cylinders in a single or double frame.

✅ Every/alternate cylinder can have an individual geared motor drive if required.

✅ An Individual trapping system for faster condensate removal from cylinders.

₹1,251,000.00

Drying Range

The Drying Range or VDR (Vertical Drying Range) is one of the most demanding processing machinery in Woven dyeing & printing plants. The Drying Range has the following features that make it an essential part of the plant.

- Firstly, It ensures rapid drying of fabric at high steam pressure.

- In other words, It is suitable for fabric drying, semi-drying, and fabric that doesn’t require heat setting or Clothes which need semi-dry or completely dry.

- Secondly, a Belt drive or individual drive for tensionless and crease-free passage of fabric on the cylinder result in the cloth moving smoothly.

- Thirdly, an Individual trapping system for faster condensate removal from inside of chambers.

- Therefore, it keeps cylinders at maximum heat.

- Fourthly, the working width options from 1250mm to 3500mm according to the client’s need.

- Fifthly, ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester can be rolled on this machine.

- Sixthly and most Important Drying Range has the option of 6, 8, 10, 12, 16, 20, or 24 cylinders in a single or double frame.

Above all, more numbers of cylinders equal more speed.

In conclusion, this machine is best suitable for Dyeing and Printing Plants.

🔸 Advantages:

➡ Long Lasting & sturdy construction

➡ Lowest consumption data

➡ Quick heating up

➡ Easy to operate

➡ Drying with minimum tension

➡ Crease-free fabric passage

➡ Perfect temperature uniformity across fabric width

➡ Highest product quality

➡ Shut off valves for cylinders

➡ Lowest maintenance effort

➡ Lowest radial run out and perfect welding workmanship

🔸 Technical Specification:

✅ Box type or beam stack structures as per choice.

✅ Belt drive or individual drive for tension-less and crease-free passage for fabric on cylinders.

✅ Options of two bowls or three bowls mangle to attached with cylinder dryer as per customer need.

✅ Any width from 1250mm to 3500mm of the dryer is supplied.

✅ The drying Range has the option of 6, 8, 10, 12, 16, 20, or 24 cylinders in a single or double frame.

✅ Every/alternate cylinder can have an individual geared motor drive if required.

✅ An Individual trapping system for faster condensate removal from cylinders.

🔸 Payment, Taxes and Delivery

Payment: 40% Advance Balance against Proforma Invoice prior to dispatch.

Delivery: Delivery of the machine ideally comes within 4 to 6 weeks.

Tax: GST 18% (Domestic orders) Or As per Government (export orders).

Transport Charges: Extra to your account.

Insurance: To be arranged by you.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Drying Range | Fabric Processing Machine | 6 to 24 Cylinders | New & Advanced

The drying range known as VDR or Vertical drying range machine ensures rapid drying of fabric at high steam pressure to dry or semi-dry the cloth.

Product SKU: P/DR-1

Product Brand: Indian

Product Currency: INR

Product Price: 12,51,000

Price Valid Until: 2028-01-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

SKU: N/A

Category: Processing Machinery

Tags: Cylinder Drying Range, drying range, fabric processing machinery

| Fabric | Cotton, Cotton/Polyester, Rayon, Viscose, Wool, Other Woven Blends |

|---|---|

| Machine Width | 1250mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2200mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm, 3400mm, 3500mm |

| Cylinder | 6, 8, 10, 12, 16, 20, 24 |

Drying Range | Fabric Processing Machine | 6 to 24 Cylinders | New & Advanced

The drying range known as VDR or Vertical drying range machine ensures rapid drying of fabric at high steam pressure to dry or semi-dry the cloth.

Product SKU: P/DR-1

Product Brand: Indian

Product Currency: INR

Product Price: 12,51,000

Price Valid Until: 2028-01-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

Youtube

Belt Drive Cylinder Drying Range

Individual Drive Cylinder Drying Range

Drying Range | Fabric Processing Machine | 6 to 24 Cylinders | New & Advanced

The drying range known as VDR or Vertical drying range machine ensures rapid drying of fabric at high steam pressure to dry or semi-dry the cloth.

Product SKU: P/DR-1

Product Brand: Indian

Product Currency: INR

Product Price: 12,51,000

Price Valid Until: 2028-01-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

Based on 0 reviews

0.0 overall

0

0

0

0

0

Be the first to review “Cylinder Drying Range” Cancel reply

- Finishing Machinery

Stenter

0 out of 5(0)The Stenter or Hot air Stenter Machine is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities give the fabric the final result of all the processes it went through.

Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out.

It also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.🔶 Efficiency

✅ Double-jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advanced chamber technology makes it easy to install and reinstall if needed without interfering with the performance.Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

SKU: S001₹3,000,000.00 This product has multiple variants. The options may be chosen on the product page - Washing Machinery

Open Width Washing Range

0 out of 5(0)Open width Washing Range

Open width Washing Range is for the fabric washing machine for woven fabrics. The Open width Washing Range machine has the following features.

- Firstly, The system consists of a specially shaped impeller in the drum in which water jets uniformly smashes the full fabric width very high washing performance on the upper and backside of the fabric.

- In other words, Open width Washing Range removes unfixed dyestuff, gum, and other chemicals from the fabric.

- Secondly, Washing with tanks can carry out pre-washing, rinsing, and chemical treatment.

- Therefore, Open width Washing Range improves fabric quality.

- An effective squeezer between the washing unit gives maximum liquor separation from one bath to another.

- Thirdly, Each washing compartment with its force-spray system, re-circulation pump, filtering device, overflow, drain, and heating arrangement.

- Fourthly, the Open width Washing Range’s working width is to be made from 1500mm to 3500mm depending on the client’s need.

- Fifthly, ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabric can be processed on this machine.

- Sixth and most Important is Perfect synchronizing of linear speed hence tension-less and creaseless transport of fabric all along the process.

🔶 ADVANTAGES :

✅ Excellent Washing efficiency.

✅ Extremely sturdy construction.

✅ Quiet running.

✅ Low energy consumption.

✅ Ease of operation.

✅ Optional knife spray between each strand of fabric with supply from a separate pump.

✅ Circulation and counter flow arrangement to save water.

✅ Low maintenance.

✅ Quick and simple installation.

✅ Tight closing glass windows on the sides to provide easy access.

✅ Direct steam heating by perforated S S Pipes.

✅ S S bottom rolls running in self-aligning bush bearing.

SKU: n/a₹7,100,000.00 This product has multiple variants. The options may be chosen on the product page - Batching, Makeup Machinery

Palletizing Machine

0 out of 5(0)- Custom made Machine, Fabric width on request.

- Maximum Capacity: 1500meters.

- Working table descends up to 78” (2000mm).

- Length of folds adjustable up to 1.00 meter.

- Rigid structure of M.S. Channel to withstand width and weight of the fabric.

- Folding blades are mounted on the carriage off steel roller chain.

- A simple device for exact adjustment of the folding blades

- Hydraulic System for counterbalancing of the platform comprising of double acting hydraulic cylinder and hydraulic power pack for pushing and pulling of the table: Capacity 1000kg.

- Standing platform at double folding level.

- Ladder for climbing up to the double folding level.

- Main Electric Motor 3hp x 1000rpm with suitable starter and switches.

[spbsm-follow-buttons]

SKU: n/a₹500,000.00 - Finishing Machinery

Denim Finishing Range

0 out of 5(0)Denim Finishing Range

The Denim Finishing Range Exclusive purpose is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Denim Finishing Range is available for up to 3600mm working width fabric to assure total shrinkage protection to Denim fabrics.

Denim Finishing Range was developed in a way that can shrinkage up to 14% in a single passage.

Denim Finishing Range is usually the last process in the sequence of fabric finishing. The Denim fabric processed in Denim Finishing Range gets fully shrunk.

Before Denim Finishing Range, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Key Features:

✅ Ensuring Required Shrinkage of 14 Ounce Denim in Single RUN At a Speed of 40 to 50 Mtrs / Min.

✅ Matching all parameters of Shrinkage, Feel, Warp & Weft Tension.

✅ Complete Machine with P.L.C. Controlled Inverter Drive.

✅ Large Touch Screen, Showing Shrinkage, Speed and Other Data, Minimum Usage, of Steam & Power.

✅ User-friendly machine with the shortest Payback time.

✅ Can finish lycra fabrics in a single run with required weft and warp shrinkage at the speed of 40 mt / min.

✅ Specially designed heavy warp pull to control the width of the fabric and warp stretch control by P L C.

✅ Motorized antiskew device to control the skew setting of fabric twill by forwarding and reversing the movement of motors.

✅ Specially developed a shrinking unit to achieve shrinkage up to 14 % depending upon the quality of the fabric with residual shrinkage of 1 %.

✅ 2500mm dia Mirror polished Jacketed main palmer cylinder with rotary joints.

✅ The number of 2 cooling cylinders is provided at the exit of the palmer unit to cool down the fabrics.

⭕ Singing unit at the feeding side. (Optional)

⭕ Brushing unit at feeding side. (Optional)

⭕ Temperature controlling of shrinkage and palmer unit by PLC. (Optional)

⭕ Big Batching device with ‘J’ scray at plating side. (Optional)

SKU: F/DFR-1₹17,500,000.00 This product has multiple variants. The options may be chosen on the product page - Accessories

A Frame

0 out of 5(0)A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1₹35,000.00 This product has multiple variants. The options may be chosen on the product page - Finishing Machinery

Relax dryer

0 out of 5(0)The Relax Dryer is the finishing machine to dry hosiery fabric after the fabric has been washed or processed. This Relax Dryer has the following features in it.

- Firstly, The air movement produces undulations in the cloth & at the same time, it expands the knitted fabric causing dimensional shrinkage and selvedge opening.

- In other words, Relax Dryer expands the fabric width while drying it.

- Secondly, Relax Dryer rolls ladder-proof fabrics based on well-known the principle of air impact drying system.

- Thirdly, the cloth moved through the drying chamber on a conveyor belt that overfed to increase length shrinkage.

- Fourthly, The operating width of the Relax Dryer can range from 1600mm to 4200mm. Depending on the specific needs of the client.

- Fifthly, Relax Dryer can process fabric ranging from 70 to 700 gsm/meter square of hosiery.

- Sixth and most Important, velocity can be achieved up to 60 meters per minute while performing the process.

In conclusion, Relax Dryer is best suitable for Dyeing & Printing units.

🔸 Technical Specification

✅The number of chambers: 2 to 8.

✅Conveyor belt width: 1600mm to 4200mm.

✅ Heating system alternatives: Natural Gas, LPG, Steam or Thermic Oil.

✅ Mechanical belt speed: Step less than 0 to 60m/min.

✅ Maximum working temperature: 220 °C.

✅ Blowers: Special design, highly efficient, diagonal location, two blowers in each chamber.

✅ Fabric feeding: Step-less by multiple points.

✅ Conveyor belt direction control: Electro-pneumatic from both sides.SKU: RD001₹2,500,000.00 This product has multiple variants. The options may be chosen on the product page

Related products

- Processing Machinery

Polymeriser

0 out of 5(0)Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.SKU: P001₹4,000,000.00 This product has multiple variants. The options may be chosen on the product page - Processing Machinery

Chainless Merceriser

0 out of 5(0)Chainless Merceriser

The Chainless Merceriser is the most Significant procedure for the cloth. Chainless Merceriser machine there are following features in it.

- To begin with, Chainless Merceriser is one of the most fundamental steps for finishing cotton fabrics. Merceriser involves treating organic material with high-caustic soda solutions. In other words, it eliminates impurities or undesired particles from the cloth before completing other processes.

- Secondly, It rolls cloth on batching trolley from fold/loose form by pressure roll assisted with twin – Pneumatic Cylinders, AC Motor & Gearbox.

- Thirdly, The caustic soda-impregnated Fiber reflects light, making it brighter. It also boosts hygroscopicity, strength, and dye affinity.

- Fourthly, The operating width of a chainless merceriser can range from 1500mm to 3500 mm, as preferred by the customer.

- Fifthly, It can process woven fabrics with capacities ranging from 70 to 700 grammes per square metre.

- Lastly, It is available in various sizes and speeds ranging from 8 to 40 metres per minute.

In conclusion, this merceriser machine is best suitable for the garment industry Dyeing & printing plants.

🔸 ADVANTAGES :

➡ Increase dye Affinity

➡ Improve Luster

➡ Add more Tensile Strength

➡ Increase Dimensional Stability of Warp & Weft yarn.

➡ Elimination of immature or Dead Cotton

➡ Improved Handling effects.

➡ Tailored to the customer’s specifications.SKU: P/CM-1₹6,000,000.00 This product has multiple variants. The options may be chosen on the product page - Processing Machinery

Desizing Machine

0 out of 5(0)Desizing machine

Desizing is the process of removing the size applied during weaving. The purpose of this fabric processing machinery Desizing machine is to remove the sizing ingredients such as starches, gums, PVA etc.

The starch has to be degraded into less water-soluble molecules by hydrolysis. The hydrolysis of starch using enzymes under particular concentration, temperature and duration is called desizing.

Desizing can do at room temperature to boiling temperature as per the quality of the enzyme.

Desizing Tank is made from Stainless Steel material. The tank can have open or fully enclosed construction as per requirement. The number of rollers in the tank facilitates suitable liquor takeup of every kind of fabric which is to be desized.

Desizing machine speed can be lowered or raised for proper take-up of the liquor for different grades of cloth.

🔸 Key Functions:

✅ 5 to 60Mtrs/Min operational speed.

⭕ Automatic or manual dozing system (Optional)

✅ Auto Steam Control.

✅ Easy usage.

⭕ Chemical preparation tanks (Optional)

✅ Desizing machines are available from 1600mm to 3400mm fabric width.

SKU: P/DM-1₹1,800,000.00 This product has multiple variants. The options may be chosen on the product page

There are no reviews yet.