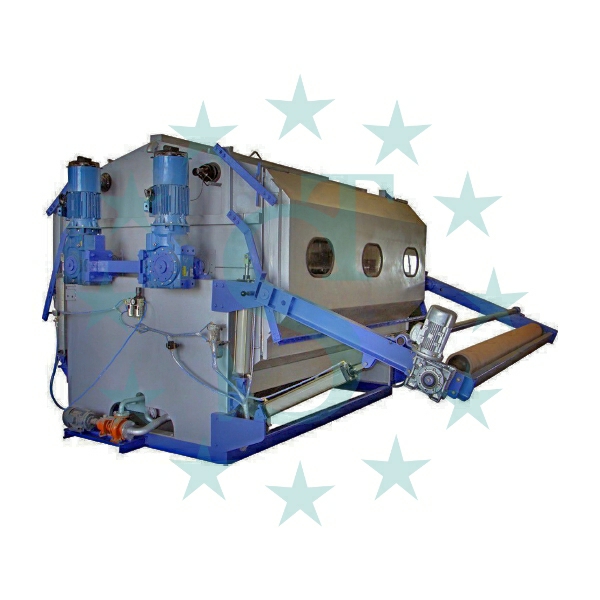

Automatic Jigger

Automatic JIGGER is one of the best dyeing machine inventions for simplifying the dying process. Automatic JIGGER is a Hybrid of hydraulic & conventional JIGGER.

Automatic JIGGER comes with two types 1st one is OPEN TYPE & other one is CLOSE TYPE.

Where One-hand OPEN TYPE Automatic JIGGER comes with all the benefits like

✅ Auto tension control

✅ Auto speed control

✅ Auto cycle control

✅ Circulation system with filters to avoid centre to selvedge

✅ Suitable for any exhaust pre-treatment, dyeing & finish process

✅ Tension setting device to avoid running crease & machine jerks

⭕ Auto pendulum control (optional)

⭕ Batching or winch device (optional)

⭕ Auto water level controller (optional)

⭕ Pneumatic operated drain (optional)

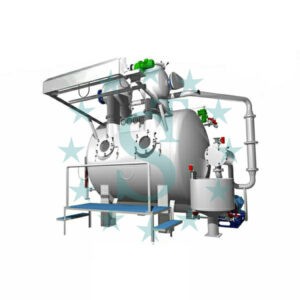

Otherhand CLOSE TYPE Automatic JIGGER comes with the additional features like

✅ Auto circulation system

✅ Auto temperature controller

✅ A fully covered jigger will save utilities

⭕ Dosing side tank facility (optional)

⭕ Circulation system with filters to avoid centre to narrow border (optional)

The tension control system allows Automatic JIGGER to dye any fabric with ease. One operator can run four Automatic JIGGER machines simultaneously thanks to its PLC system, and the individual drive “automatic dyeing jigger” runs on zero tension on the fabric.

Automatic JIGGER uses both rollers powered by separate gearboxes and motors on inverter drives which do wonders for uniform dyes, even when running at varying speeds.

In conclusion, it is the best-woven dyeing machine, fabric dyeing machine or Cotton dyeing machine.

🔶 Technical Specification

✅ Capacity: 300 Kg. to 2000 kg. [OPEN]

✅ Capacity: 500 Kg. to 2000 kg. [CLOSE]

✅ Available Width: 1250mm to 3400mm

✅ S.S. Structure 304 Out Outer body 316 mail rolls plus inner bottom

✅ 0 to 10 Kgs. (Tension less operation Possible)

✅ Suitable for any Fabric from 30gsm to 500gsm

✅ S.S. Cladded Main Roll

✅ Pneumatic cylinders operated doors [CLOSE]

✅ Individual drive on each roller

✅Speed & tension control through a drive

₹550,000.00

CompareAUTOMATIC JIGGER

Automatic JIGGER is one of the best dyeing machine inventions for simplifying the dying process. Automatic JIGGER is a Hybrid of hydraulic & conventional JIGGER.

Automatic JIGGER comes with two types 1st one is OPEN TYPE as well 2nd one is CLOSE TYPE.

Where One-hand OPEN TYPE comes with all the benefits like

✅ Auto tension control

✅ Auto speed control

✅ Auto cycle control

✅ Circulation system with filters to avoid centre to selvedge

✅ Suitable for any exhaust pre-treatment, dyeing & finish process

✅ Tension setting device to avoid running crease & machine jerks

⭕ Auto pendulum control (optional)

⭕ Batching or winch device (optional)

⭕ Auto water level controller (optional)

⭕ Pneumatic operated drain (optional)

Otherhand CLOSE TYPE comes with the additional features like

✅ Auto circulation system

✅ Auto temperature controller

✅ A fully covered jigger will save utilities

⭕ Dosing side tank facility (optional)

⭕ Circulation system with filters to avoid centre to the edge (optional)

The tension control system allows dyeing nearly any fabric automatically with ease. One operator can run four machines simultaneously thanks to its PLC system, and the individual drive “automatic dyeing jigger” runs on zero tension on the fabric.

It uses both rollers sets powered by separate gearboxes and motors on inverter drives which can do wonders for giving uniform dyes, even when running at varying speeds.

🔶 Technical Specification

✅ Capacity: 300 Kg. to 2000Kg. [OPEN]

✅ Capacity: 500 Kg. to 2000Kg. [CLOSE]

✅ Available Width : 1250mm to 3400mm

✅ S.S. Structure 304 Out Outer body 316 mail rolls plus inner bottom

✅ 0 to 10 Kgs. (Tension less operation

Possible)

✅ Suitable for any Fabric from 30gsm to 500gsm

✅ S.S. Cladded Main Roll

✅ Pneumatic cylinders operated doors [CLOSE]

✅ Individual drive on each roller

✅Speed & tension control through a drive

🔶 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

OPEN TYPE

CLOSE TYPE

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Automatic Jigger | Best Fabric dyeing machine 300-2000 kgs. | Book Online

Automatic jigger is a new fabric dyeing machine or say hybrid version of a simple jigger and hydraulic jigger this jigger can dye all woven fabrics like cotton.

Product SKU: D/AJ-1

Product Brand: Indian

Product Currency: ₹

Product Price: 550000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

| Type | OPEN, CLOSE |

|---|---|

| Capacity | 300 Kg, 350 Kg, 500 Kg, 750 Kg, 1000 Kg, 1250 Kg, 1500 Kg, 1750 Kg, 2000 Kg |

| Machine width | 1250mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2200mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm, 3400mm |

| Fabric | Cotton, Cotton Polyester, Wool, Canvas |

Automatic Jigger | Best Fabric dyeing machine 300-2000 kgs. | Book Online

Automatic jigger is a new fabric dyeing machine or say hybrid version of a simple jigger and hydraulic jigger this jigger can dye all woven fabrics like cotton.

Product SKU: D/AJ-1

Product Brand: Indian

Product Currency: ₹

Product Price: 550000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

Youtube

Automatic Jigger | Best Fabric dyeing machine 300-2000 kgs. | Book Online

Automatic jigger is a new fabric dyeing machine or say hybrid version of a simple jigger and hydraulic jigger this jigger can dye all woven fabrics like cotton.

Product SKU: D/AJ-1

Product Brand: Indian

Product Currency: ₹

Product Price: 550000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

Based on 0 reviews

Be the first to review “Automatic Jigger”

-

Value Adding Machinery

SOFT FEEL Surface Finish

SOFT FEEL

is a new revolutionary way to create beautiful fabrics.

In other words, It is value-adding machinery that gives the fabric a soft and smooth finish.

SOFT FEEL obtains a mix of different grains of abrasive bands and abrasive brushes complete range of SUEDING and BRUSHING.

Because of increasing demand in domestic and export markets for consistent gentle and soft surface finish.

We have developed the latest SOFT FEEL surface finish machine for exceedingly smooth and even surface treatment on dry fabric like suiting, shirting, dress materials and denim.

SOFT FEEL’s Powerful fluff suction keeps fabric, brush rollers, and the inside area clean and dust-free. Therefore, it helps machinery to be low maintenance.

SOFT FEEL is committed to producing an infinitely adjustable smooth surface with an outstanding repeat accuracy of the desired effect.

SOFT FEEL comes with 3 Brush Rolls / 4 Brush Rolls and 6 Brush Rolls according to the client’s needs.

SOFT FEEL can process fabric ranging from 70 gsm/meter square to 700 gsm/meter square.

SOFT FEEL‘s working width is to be made from 1900mm to 2600mm depending on the client’s need.

🔶 ADVANTAGE:

➜ Compact Design

➜ Clear visibility of the ongoing process.

➜ Positively driven scroll roller for ceaseless fabric feeding.

➜ Rotating Pressing arrangement.

➜ Variable brush speed for required feel.

➜ Powerful fluff suction keeps fabric with brush rollers and the inside area

clean and dust free.

➜ Multi point inverter controlled drive ensures controlled fabric tension.

➜ Built-in electrical panel.

➜ User-friendly Touch Screen display.

➜ Plaiting down or optional friction batch.

Follow/Share/Visit Us on

[DISPLAY_ULTIMATE_SOCIAL_ICONS]

SKU: WIZ06 -

Dyeing Machinery

Multi-Nozzle Soft flow

Multi-Nozzle Soft Flow is a Low/High-Temperature dyeing machine technology that works as a “Soft flow” or as a “Jet dyeing” machine.

The main advantage of this development is to increase the machine’s flexibility and versatility to process all types of fabrics.

The soft nozzles in this new technological advancement have a large diameter, and the fixed nozzle has an individual flow control valve, whereas the main nozzle is adjustable.

By increasing and decreasing the gap of a nozzle, flow and pressure increase or decrease as per fabric quality demand.

To run Multi-Nozzle Soft Flow as a soft flow machine, increase the gap Which, subsequently decreases the pressure and increases water flow,

At the time, all three nozzles worked as Soft flow & water flow gets controlled individually by the control valve As per fabric quality demand.

To run The Multi-Nozzle Soft Flow as a “Jet dyeing” Machine lowering the gap of a nozzle which increases the pressure and decreases the water flow. That time close the soft-nozzle control valve.

🔸 Technical Specification

✅ Capacity: 25 to 400 kg. (Single Tube)

✅ Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye –30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ Max. Fabric Speed – 400 Mtr./Min.

✅ Work as a Jet Dyeing or as Soft flow to meet the requirements of all types of fabric quality.

✅ Vessel: SS 316 L.

✅ Multiple soft nozzles.

SKU: D/MSF-1 -

Dyeing Machinery

Jigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

SKU: jigger -

Dyeing Machinery

Atmospheric Soft Over Flow

Atmospheric Soft flow

The Atmospheric Soft Flow machine is the same as HTHP Soft flow Dyeing machine. The only difference is Atmospheric Soft Flow works at low temperatures & without pressure.

Some fabrics like Cotton & Cotton blends don’t require high temperatures. In that case, Soft Flow is very much suitable because Atmospheric Soft Flow reduces the running cost by saving energy. In short, it is a Cotton dyeing machine.

Furthermore, the liquor ratio of the Soft Flow machine is lower than that of the HTHP Soft Flow machine.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:4 (wet Fabric)

✅ Capacity: 50 to 1200 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ Maximum Temprature – Up to 98° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/ASF-1 -

Accessories

Roll Wrapping

Roll Wrapping

Fabric Roll wrapping machine is one of the most required Accessories for pre-delivery processes in Textile plants and Mills. The primary object of the fabric roll wrapping machine is to wrap ready-to-ship rolls so that the fabric remains safe while being delivered to the customer.

Fabric Roll wrapping machines can wrap material rolls of Denim Cloth, Curtain Cloth, Carpets, Foam sheets, Upholsteries, Fabrics, Film, Paper etc. which have a Maximum roller height from ground level up to 400 millimetres.

The fabric Roll wrapping machine is simple to operate, and the sturdy & safe control panel makes it easy to load and unload the fabric roll with the ease of integration into conveyor lines.

With a speed of up to 50 meters per minute, making 20 to 40 rolls per hour while performing variable overlap, amount of stretch, and roller speed, the fabric roll wrapping machine saves labour, time and money.

Because of its unique construction, traverse can accommodate a variety of roll widths. Maximum stretch Power Roller Pre-Stretch Carriage with Pre-Stretch Ratio adjustable up to 300% (Depending upon Film Gauge & Quality).

Inshot fabric Roll wrapping/Stretch wrap machines make it possible to wrap, store and protect ready-to-ship rolls while protecting rolls from dirt and damage.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ Maximum roller height from ground level up to 400mm can be processed.

✅ Speed up to 50 meters/minute.

✅ Maximum stretch Power Roller Pre-Stretch Carriage with Pre-Stretch Ratio adjustable up to 300% (Depending upon Film Gauge & Quality).

✅ Rolls/Hour: 20-40 rolls.

✅ Weight/Roll: 400kgs

✅ Roll Diameter: 600mm

✅ Roll Width: 2100mm (As Par Fabric width)

SKU: A/WR-1-1 -

Finishing Machinery

Compressive Shrinking Range

The Sole purpose of the Controlled Compressive Shrinking Range or ZEROZERO is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Controlled Compressive Shrinking Range or ZEROZERO are available up to 3200mm working width fabric to assure total shrinkage protection to woven fabrics. It can be 100% cotton, cotton/polyester, cotton/viscose or tough and heaviest fabric like denim. Compressive Shrinking Range or ZEROZERO developed in a way that can shrinkage up to 12% in a single passage.

The most capable of shrinking medium, lightweight fabric to the heaviest denim, cotton blended suiting & shirting by watering cotton, terylene, hemp and its blends to shrink the cloth to meet the requirements of shrinkage, stabilization and improve the hand touch.

A controlled Compressive Shrinking Range is usually the last process in the sequence of fabric finishing. The woven fabric processed in the machine gets fully shrunk.

Before compressive shrinking, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Technical Specification

✅ A.C. frequency conversion transmission, designed speed: 10-80m/minute.

✅ Shrinkage 0 – 12 % depending upon fabric quality.

✅ Minimum and controlled tension.

⭕ Imported Rubber Blanket and Polyester Felt will be provided optionally.

✅ A Jacketed drum in 1500mm, 2000mm and 2500mm diameters.

✅ Stainless Steel damping & conditioning unit supplied as standard Parts.

SKU: n/a

There are no reviews yet.