No products in the cart.

Dyeing Machinery

Regular Jet

Regular Jet dyeing

This machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside this polyester dyeing machine moves solely due to the force of water.

It is user-friendly because, If we compare it with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 L

Best Polyester dyeing machine with a low liquor ratio in a Jet dyeing form.

₹751,000.00

Regular Jet Dyeing

A Regular Jet dyeing machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside Regular Jet dyeing moves solely due to the force of water.

Regular Jet dyeing is user-friendly because, If we compare Regular Jet with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 L

🔸 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Regular jet | Fabric dyeing machine | 25 to 400 kgs. | Best for Polyester

A regular jet dying machine is a polyester dyeing machine in which the fabric moves with only the force of water. cause of the low liquor ratio It's economical.

Product SKU: D/RJ-1

Product Brand: Indian

Product Currency: ₹

Product Price: 7,51,000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

| Capacity | 25Kg, 50Kg, 75Kg, 100Kg, 150Kg, 200Kg, 250Kg, 300Kg, 400 Kg |

|---|---|

| Nossel size | 105mm, 120mm, 140mm, 200mm, 250mm, 300mm |

| Fabric | POLYESTER, WOVEN, KNITTED, POLYESTER NET, SATIN, GEORGETTE, OTHER |

Regular jet | Fabric dyeing machine | 25 to 400 kgs. | Best for Polyester

A regular jet dying machine is a polyester dyeing machine in which the fabric moves with only the force of water. cause of the low liquor ratio It's economical.

Product SKU: D/RJ-1

Product Brand: Indian

Product Currency: ₹

Product Price: 7,51,000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

Based on 0 reviews

Be the first to review “Regular Jet”

- Accessories

Roll Wrapping

Roll Wrapping

Fabric Roll wrapping machine is one of the most required Accessories for pre-delivery processes in Textile plants and Mills. The primary object of the fabric roll wrapping machine is to wrap ready-to-ship rolls so that the fabric remains safe while being delivered to the customer.

Fabric Roll wrapping machines can wrap material rolls of Denim Cloth, Curtain Cloth, Carpets, Foam sheets, Upholsteries, Fabrics, Film, Paper etc. which have a Maximum roller height from ground level up to 400 millimetres.

The fabric Roll wrapping machine is simple to operate, and the sturdy & safe control panel makes it easy to load and unload the fabric roll with the ease of integration into conveyor lines.

With a speed of up to 50 meters per minute, making 20 to 40 rolls per hour while performing variable overlap, amount of stretch, and roller speed, the fabric roll wrapping machine saves labour, time and money.

Because of its unique construction, traverse can accommodate a variety of roll widths. Maximum stretch Power Roller Pre-Stretch Carriage with Pre-Stretch Ratio adjustable up to 300% (Depending upon Film Gauge & Quality).

Inshot fabric Roll wrapping/Stretch wrap machines make it possible to wrap, store and protect ready-to-ship rolls while protecting rolls from dirt and damage.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ Maximum roller height from ground level up to 400mm can be processed.

✅ Speed up to 50 meters/minute.

✅ Maximum stretch Power Roller Pre-Stretch Carriage with Pre-Stretch Ratio adjustable up to 300% (Depending upon Film Gauge & Quality).

✅ Rolls/Hour: 20-40 rolls.

✅ Weight/Roll: 400kgs

✅ Roll Diameter: 600mm

✅ Roll Width: 2100mm (As Par Fabric width)

SKU: A/WR-1-1 - Boiler, Heating Solution

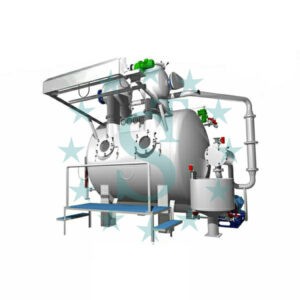

Gas Boiler

GAS Boiler

The Gas Boiler is a packaged three-pass smoke tube with a total wet back boiler. Gas Boiler comes in two three series for burning light oils & gas and heavy oils.

The Gas Boiler also can be customized to a complete skid mount unit on customer demand.

When fitted with a particular burner, these boilers are ideal for burning waste gases like biogas from the decomposition of organic matter in distilleries.

🔸 PRODUCTS FEATURES:

✅ Three-pass smoke tube with complete wet back boiler.

⭕ Multi-fuel option – light oils/heavy oils/gases

✅ High efficiency of about 88% to 95%

✅ High dryness fraction steam increases usable heat.

✅ Gas Boiler Comes with mono-block/ dual block/steam atomized burner with world-renowned Technology from (ITALY)

⭕ An additional option of oil pre-heater confirming EN safety standards

✅Corrugated furnaces for boilers above 6 TPH capacity.

⭕ Optional PLC-based control panels that would be linked to SCADA or DCS systems.🔸 Operating Range:

➡ Capacities In the range of 1.0 TPH to 15 TPH

➡ Pressure: In the range of 10.54 to 17.54 Kg/cm2 (g)

➡ Firing fuels: LDO, FO, LSHS & Natural Gas

➡ Efficiency: Overall efficiency of 88 % (+/-2%) on NCVSKU: H/GB-1 - Processing Machinery

Polymeriser

Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.SKU: P001 - Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 - Finishing Machinery

Loop Ager

Loop Ager

Loop Ager can be offered in five variants as mentioned below:

- DIGIFIX Specially designed Machine for Digital Printing

- ATMOFIX suitable for Low-Temperature Application

- EVOMAX suitable for High-Temperature Applications

- RAPIFIX suitable for Hot Air and Pigment Application

- UNIFIX is appropriate for both Low Temperature & High-Temperature applications

Loop agers are simple to use on almost any fabric that has been printed using different printing recipes. The high versatility of steam agers, together with high qualitative standards, allows their utilization in all continuous production lines for the colour fixation processes.

❇ ATMOFIX Loop Agers, the quantity of steam is injected more at the entry of the fabric as on the first few loops.

Moisture condenses on the cloth with the Exothermic reaction for colour fixation. UREA dissociation takes place in the initial few seconds By when the water vapour is distributed/injected into the chamber accordingly.

❇ EVOMAX Loop Agers are suitable for high-temperature streaming applications.

The Steam consumption is comparatively less because of the compact design of chambers manufactured by SS 316 with larger Thermos Oil Radiators/ Heaters/Gas Burners installed to heat the section faster when processing with High-Temperature steaming applications or Hot Air applications.

❇ RAPIFIX Loop Agers are robust and suitable for any working atmosphere. Curing Machines constructed of Mild Steel on the inside with an outer body made of Insulating Panels are fit for this process because the required temperature is above 130°C & the machine operates in moisture-free conditions on the inside.

Essentially, the Dyes are set to the cloth during the Curing Process by polymerization in hot air at 150°C to 160°C.

Loop Agers fabric moves in tensionless conditions. So, there are no chances for lengthwise stretching and no rubbing effect on the cloth.

In any ageing machine, the transportation of the fabric in the hanging loop form makes the fabric move in a tensionless motion.Oil radiators & centrifugal blowers are provided which help circulation Of the surrounding air through the filters & blows it into the machine from the bottom part of the machine.

An exhaust fan removes the Hydrocarbons & Condensed Oil.

🔸 Key features of the Loop Ager Machine:

1. Compact steaming chamber design to reduce steam consumption.

2. Even the distribution of steam in the chamber, steam injected from the top & lighter than the air will force to remove air and exhaust from the bottom will be occupied in the process chamber fully make it leaving no chance of air inside the steaming compartment.

3. Optimum steam conditioning and humidification with parallel flow inside the steamer.

4. Conveyor rollers treated with shot blasting that rotates on their axis to prevent marking off from the rod itself.

5. A loop rod roller mechanism is used to create loops.

6. The steaming chamber is a closed type made of stainless steel.

7. For low-temperature steaming of the chamber roof and entry, the delivery slit is heated by steam coils preventing condensation and dripping on the fabric.

8. DIGIFIX, ATMOFIX and UNIFIX Loop Agers are equipped with a special device steam saturator that conditions the steam. It passes through the water before being injected into the steaming chamber.

These characteristics of steam pre-conditioning help prevent and control the exothermic reaction of the fabric with the printing paste. Making the machine unique & use The temperature control system/moisturising system for the said machines is the basis of the remarkable success achieved in the textile industries for Low-Temperature Applications.

9. The EVOMAX and UNIFIX Loop Agers are fitted with an effective re-circulation system and heat exchanger using either thermic fluid or direct gas fire system for high-temperature steaming, ensuring uniform temperature throughout the chamber.

10. A unique system to allow air to re-circulate in our RAPIFIX Loop Ager instead of steam permits Polymerization treatment with stifling air up to 160 ͦC.

11. Two enormous size access windows are provided on the front side, two small inspection windows on the back side and one small size window on the Drive arrangement platform.

12. Steam exhaust fan driven by variable speed AC motor, all fabric movements are pushed by variable speed AC motor.

13. Automatic control PLC system for programming and monitoring steam quantity, steam pressure, processing time & temperature is optional with our “PRO” version of all the variants of Loop Agers and Curing machines.

14. “LITE” versions of machines are also available for all variants of Agers and Curing machines for Manual operations and are also equipped with Modbus protocol and a 7” HMI for comfortable functions.

SKU: n/a - Dyeing Machinery

CP Dyeing

CP Dyeing

CP Dyeing is dyeing machinery to Dye Fabrics rapidly. Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.SKU: n/a

There are no reviews yet.