No products in the cart.

Finishing Machinery

Stenter

The Stenter or Hot air Stenter Machine is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities give the fabric the final result of all the processes it went through.

Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out.

It also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.

🔶 Efficiency

✅ Double-jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.

🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advanced chamber technology makes it easy to install and reinstall if needed without interfering with the performance.

Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

₹3,000,000.00

Stenter

The Stenter is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities to give the fabric the final result of all the processes it went through. Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out. Stenter also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.

🔶 Efficiency

✅ Double jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.

🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advance chamber technology makes it easy to install and reinstall if needed without interfering with the performance.

Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Stenter | Fabric Finishing Machine | Book 1 to 12 Chambers | Accurate

purpose of the stenter or hot air machine is to heat setting the fabric and to stretch it's width wise to recover the uniform width. It comes with customize sizes.

Product SKU: F/S-1

Product Brand: Indian

Product Currency: INR

Product Price: 3000000

Price Valid Until: 2027-08-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

| Fabric | Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar |

|---|---|

| Fabric Width | 1600mm, 1800mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm, 3400mm |

| Chambers | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 |

Stenter | Fabric Finishing Machine | Book 1 to 12 Chambers | Accurate

purpose of the stenter or hot air machine is to heat setting the fabric and to stretch it's width wise to recover the uniform width. It comes with customize sizes.

Product SKU: F/S-1

Product Brand: Indian

Product Currency: INR

Product Price: 3000000

Price Valid Until: 2027-08-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

Youtube

Coming Soon

Stenter | Fabric Finishing Machine | Book 1 to 12 Chambers | Accurate

purpose of the stenter or hot air machine is to heat setting the fabric and to stretch it's width wise to recover the uniform width. It comes with customize sizes.

Product SKU: F/S-1

Product Brand: Indian

Product Currency: INR

Product Price: 3000000

Price Valid Until: 2027-08-01

Product In-Stock: PreOrder

Editor's Rating:

5

5

Based on 0 reviews

Be the first to review “Stenter”

- Dyeing Machinery

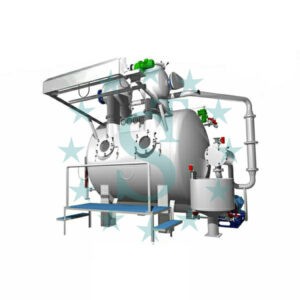

HT.HP. Soft Over Flow

HTHP Soft Over Flow is just like the HTHP Soft Flow machine with a bigger capacity & for heavy fabrics.

HTHP Soft Over Flow is Specially Designed to process Heavy and sensitive fabrics like Terry Towel, and Curtain Bedsheet of 100% Cotton knit and woven fabrics. In short, it’s a Terry towel dyeing machine.

HTHP Soft Over Flow can work as a Soft Overflow with minor adjustments.

A larger nozzle diameter, with a Higher volume & low-pressure nozzle design and inside Teflon sheet are helpful to move the fabric very smoothly and gently without damaging the cloth.

A specially develop online filter design helps to collect the Terry towel fumes.

🔸 Technical Specification

✅ Capacity: 50 to 2000 kg.

✅ The process has a sensitive fabric like Terry Towels, Curtain, Bed Sheet, 100% cotton knit & woven etc.

✅ Work as Soft flow or as overflow dyeing.

✅ High Temp. – Up to 140 ° C.

✅ The vessel makes of stainless steel 316 L.

✅ Specially developed a filter to collect towel fumes.

✅ Teflon Sheet inside the chamber for smooth fabric movement.

✅ High volume, Low-pressure soft nozzle with a larger diameter for heavy and Larger width fabrics

✅ Fabric drive reel with frequency controller.SKU: D/HSO-1 - Dyeing Machinery

Atmospheric Soft Over Flow

Atmospheric Soft flow

The Atmospheric Soft Flow machine is the same as HTHP Soft flow Dyeing machine. The only difference is Atmospheric Soft Flow works at low temperatures & without pressure.

Some fabrics like Cotton & Cotton blends don’t require high temperatures. In that case, Soft Flow is very much suitable because Atmospheric Soft Flow reduces the running cost by saving energy. In short, it is a Cotton dyeing machine.

Furthermore, the liquor ratio of the Soft Flow machine is lower than that of the HTHP Soft Flow machine.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:4 (wet Fabric)

✅ Capacity: 50 to 1200 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ Maximum Temprature – Up to 98° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/ASF-1 - Accessories

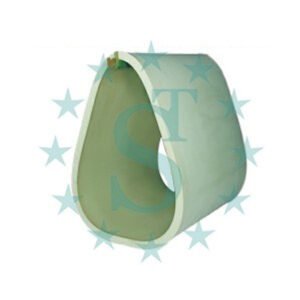

Rubber Blanket

Rubber Blanket

in the textile finishing process for pre-shrinking fine, lightweight cloth, Twills, Drills, & other medium-weight fabrics. Rubber Blanket has the following features:

- Firstly, the Rubber Blanket is produced from the highest quality, dirt-free natural rubber and selective quality polymers to give extremely high compressive strength to the product.

- Secondly, it ensures a non-stick surface for excellent fabric finish during the shrinkage process of textile.

- Thirdly, the high-quality speciality rubber additive with high-performance anti-degradants is selected to prevent surface degradation of the Rubber Blanket at high-temperature processing, which gives excellent heat resistance and superior flex life to the product.

- Fourthly, a Superior quality Rubber blanket can effortlessly process at high steam pressure on modern high-speed machines to give shrinkage-free fabrics. Because of the heat resistance nature of the Rubber Blanket, it Gives uninterrupted service before stopping the machine from grinding the new smooth surface.

- Fifthly, The good abrasive surface and excellent flex quality of the Rubber Blanket are Expected to give at least 10 to 15% higher meterage of fabric under ideal processing conditions than other brands of Rubber Banket available in the Indian market.

Moreover, Producers of lightweight, low shrinkage potential, 100% cotton or cotton/polyester, commonly report from 15 million to 20 million meters of productive life.

🔶 Technical Specification

- Hardness: The recommended hardness of a Rubber Blanket is between 36 degrees to 39 degrees depending on the fabrics to be processed.

- Fabric Width: offer current width of 1200mm to 3500mm.

- Usually, Rubber Banket should be 150 mm to 200 mm wider than FELT the cloth to be processed.

- Pressure Circumference: The standard internal circumference of the Rubber Blanket is 3962mm (13 feet)

- Thickness: The most common thickness of a Rubber Blanket is 67 mm (2.5/8″) and varies up to 70mm. The higher thickness will initially require higher force for outer surface elongation as the Blanket turns around the pressure. Results in cracks on the outer surface & will need to grind the surface frequently and often rubbing the Rubber Blanket from the inner surface. Usually, Rubber Blanket thickness depends on the required shrinkage in fabrics.

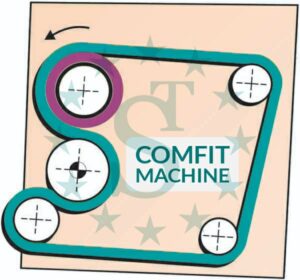

- The Rubber Blanket has a maximum shrinkage capacity of Up to 15% for lightweight fabric processed on a comfit type machine 50 mm.

- Usually, Rubber Belt thickness depends on the shrinkage needed in fabrics. For lightweight processed fabrics with low shrinkage fabrics such as poplins, fancy prints & synthetics dress material etc., a Belt thickness of 55 mm is required. This rubber belt will have a shrinkage capacity of 5-8% for processing heavy weight fabrics like Denim, Twill, Drills etc. thickness Belt of 67-71 mm is needed. The Rubber Belt has a maximum shrinkage capacity of Up to 15% for lightweight fabrics processed on a comfit type machine 50 mm A thick belt is most suitable with 3-5% shrinkage.

In conclusion, Rubber Blanket is best suitable for the garment industry or dyeing & printing plants which use the machines like Compressive Shrinking Range or Zero Zero & Comfit.

SKU: n/a - Finishing Machinery

Relax dryer

The Relax Dryer is the finishing machine to dry hosiery fabric after the fabric has been washed or processed. This Relax Dryer has the following features in it.

- Firstly, The air movement produces undulations in the cloth & at the same time, it expands the knitted fabric causing dimensional shrinkage and selvedge opening.

- In other words, Relax Dryer expands the fabric width while drying it.

- Secondly, Relax Dryer rolls ladder-proof fabrics based on well-known the principle of air impact drying system.

- Thirdly, the cloth moved through the drying chamber on a conveyor belt that overfed to increase length shrinkage.

- Fourthly, The operating width of the Relax Dryer can range from 1600mm to 4200mm. Depending on the specific needs of the client.

- Fifthly, Relax Dryer can process fabric ranging from 70 to 700 gsm/meter square of hosiery.

- Sixth and most Important, velocity can be achieved up to 60 meters per minute while performing the process.

In conclusion, Relax Dryer is best suitable for Dyeing & Printing units.

🔸 Technical Specification

✅The number of chambers: 2 to 8.

✅Conveyor belt width: 1600mm to 4200mm.

✅ Heating system alternatives: Natural Gas, LPG, Steam or Thermic Oil.

✅ Mechanical belt speed: Step less than 0 to 60m/min.

✅ Maximum working temperature: 220 °C.

✅ Blowers: Special design, highly efficient, diagonal location, two blowers in each chamber.

✅ Fabric feeding: Step-less by multiple points.

✅ Conveyor belt direction control: Electro-pneumatic from both sides.SKU: RD001 - Dyeing Machinery

Regular Jet

Regular Jet dyeing

This machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside this polyester dyeing machine moves solely due to the force of water.

It is user-friendly because, If we compare it with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 LBest Polyester dyeing machine with a low liquor ratio in a Jet dyeing form.

SKU: D/JD-1 - Accessories

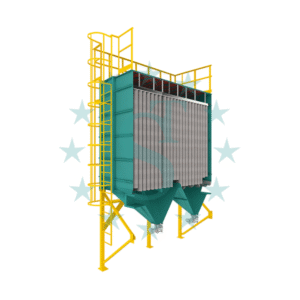

Bag Filter

Bag Filter

A Bag Filter, also known as a dust collector, is a most required Accessory for boiler houses in textile plants and mills. The primary object of the Bag filter is to clean dirty air or gas by trapping dust and particles before the air goes from the chimneys of the Plants and Mills.

The Bag filter consists of multiple woven bags. The bag filter typically holds between 56 and 320 bags, depending on the capacity of the Boiler or Thermopac. These filters effectively capture dust and particles, helping the equipment work efficiently. Their design ensures they fit well with the system while allowing necessary airflow. It has the following features that make it an essential part of Boiler Houses in Textile Plants:

- Firstly, it cleans dirty air and gases by catching them in bags before the air enters the environment.

- Secondly, it helps to contain dirt and pollutants from the air, making the workplace safer for workers and the environment.

- Thirdly, in industries like textiles, even tiny dust particles can affect the quality of the product. Bag filters help maintain a clean environment.

- Fourthly, it is a highly customizable product that can carry between 56 and 320 bags, depending on the capacity of the Boiler or Thermopac.

- Fifth and most importantly, Governments have strict rules on air pollution. Bag filters help companies follow these rules to avoid fines or shutdowns.

Conclusion:

Bag filters are essential for modern industry. They clean the air by removing dust and particles, protecting people and machines. They work efficiently, are built to last, and can be used in different industries, including textile, cement, and food production.

Using bag filters helps industries maintain clean air, comply with environmental laws, and create a safer workplace. They are a wise investment for any company seeking to enhance safety and productivity.

🔸 Technical Specification

✅ Can be customized from 56 to 320 bags.

✅ Attach with Boiler or Thermopac (Thermic Fluid Heater)

✅ From capacity 2 tons to 10 tons (Boiler) & from capacity 500U to 5000U (Thermic Fluid Heater)

SKU: A/BF-1

There are no reviews yet.