No products in the cart.

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

₹35,000.00

Summery

A-FRAME Trolley

A-frame trolley is one of the most required Accessories in Textile plants and Mills. A-frame’s objective is to carry the fabric and make it easy to maneuver inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

These trolleys are also utilized in rotating stations by simply adding an extension to them.

These trolleys come in different sizes from 44 up to 130 inches roller width, depending on the customer. trolleys take less space than bucket/box type trolleys. It gets easier to manage them and store them in one place.

🔸 Technical Specification

✅ A FRAME’s top roll is fabricated from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or as per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front-side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2″ wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

Payment, Taxes, & Delivery

- Payment: 50% advance is required, with the balance payable on the invoice.

- Delivery: The machine is ideally delivered within 2 to 4 weeks.

- Freight: Will be paid by the customer.

- Tax: GST 18% (Domestic Orders)

- Installation: ₹5000 per visit. Travelling and accommodation client scope.

Manufacture

Jio Textile

Company name: Jio Textile

Address: New Delhi

Email: inf0@jiotextile.com

Contact: +917011272325

How To Book & Buy Your Product Online?

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

A-Frame | Accessories | 44" to 130" Roller | Best for Mills

A-frame trolly is one of the most required Accessories in Textile Plant and Mills. A-frame's objective is to carry the fabric and make it easy to manoeuvre.

Product SKU: A/T-1

Product Brand: JIO Textile

Product Currency: INR

Product Price: 35000

Price Valid Until: 2025-12-31

Product In-Stock: PreOrder

Editor's Rating:

4

4

| Roller Width | 1400 mm, 1500 mm, 1600 mm, 1700 mm, 1800 mm, 1900 mm, 2000 mm, 2100 mm, 2200 mm, 2300 mm, 2400 mm, 2500 mm, 2600 mm, 2700 mm, 2800 mm, 2900 mm, 3000 mm, 3100 mm, 3200 mm |

|---|

A-Frame | Accessories | 44" to 130" Roller | Best for Mills

A-frame trolly is one of the most required Accessories in Textile Plant and Mills. A-frame's objective is to carry the fabric and make it easy to manoeuvre.

Product SKU: A/T-1

Product Brand: JIO Textile

Product Currency: INR

Product Price: 35000

Price Valid Until: 2025-12-31

Product In-Stock: PreOrder

Editor's Rating:

4

4

Youtube

A-Frame | Accessories | 44" to 130" Roller | Best for Mills

A-frame trolly is one of the most required Accessories in Textile Plant and Mills. A-frame's objective is to carry the fabric and make it easy to manoeuvre.

Product SKU: A/T-1

Product Brand: JIO Textile

Product Currency: INR

Product Price: 35000

Price Valid Until: 2025-12-31

Product In-Stock: PreOrder

Editor's Rating:

4

4

Based on 0 reviews

Be the first to review “A Frame”

- Accessories

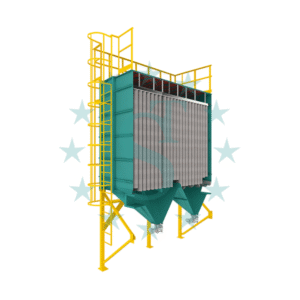

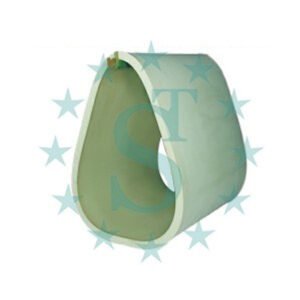

Bag Filter

Bag Filter

A Bag Filter, also known as a dust collector, is a most required Accessory for boiler houses in textile plants and mills. The primary object of the Bag filter is to clean dirty air or gas by trapping dust and particles before the air goes from the chimneys of the Plants and Mills.

The Bag filter consists of multiple woven bags. The bag filter typically holds between 56 and 320 bags, depending on the capacity of the Boiler or Thermopac. These filters effectively capture dust and particles, helping the equipment work efficiently. Their design ensures they fit well with the system while allowing necessary airflow. It has the following features that make it an essential part of Boiler Houses in Textile Plants:

- Firstly, it cleans dirty air and gases by catching them in bags before the air enters the environment.

- Secondly, it helps to contain dirt and pollutants from the air, making the workplace safer for workers and the environment.

- Thirdly, in industries like textiles, even tiny dust particles can affect the quality of the product. Bag filters help maintain a clean environment.

- Fourthly, it is a highly customizable product that can carry between 56 and 320 bags, depending on the capacity of the Boiler or Thermopac.

- Fifth and most importantly, Governments have strict rules on air pollution. Bag filters help companies follow these rules to avoid fines or shutdowns.

Conclusion:

Bag filters are essential for modern industry. They clean the air by removing dust and particles, protecting people and machines. They work efficiently, are built to last, and can be used in different industries, including textile, cement, and food production.

Using bag filters helps industries maintain clean air, comply with environmental laws, and create a safer workplace. They are a wise investment for any company seeking to enhance safety and productivity.

🔸 Technical Specification

✅ Can be customized from 56 to 320 bags.

✅ Attach with Boiler or Thermopac (Thermic Fluid Heater)

✅ From capacity 2 tons to 10 tons (Boiler) & from capacity 500U to 5000U (Thermic Fluid Heater)

SKU: A/BF-1 - Batching, Makeup Machinery

Single Folding Machine

This Single Folding machine or fabric folding machine is one of the fabric makeup machinery which has the following features :

- Firstly, the Single Folding machine does fold the fabric from a loose form to an organized plated state before performing dyeing/printing/processing operations.

- In other words, the fabric needs an inspection before starting any processes.

- Secondly, the Single Folding machine also measures fabric length before any operation or after all processes.

- Thirdly, the Single Folding machine comes in four different sizes from 41″/36 (Small)* to 72″/67 (Large)

- Fourthly, woven fabrics like cotton, viscose, rayon, wool & polyester weigh from 70 to 700 gsm/meter square and fold on a Single Folding machine.

- Fifth and most importantly, the speed can be achieved up to 50 meters per minute while performing the process.

In conclusion, this fabric folding machine is best suitable for the garment industry or dyeing & printing plants.

🔸 Technical Specification

✅ For fabric up to 1700MM

✅ The working table descends up to 15” (380 mm).

✅ Length is of folds adjustable up to 1.00 meter.

✅ Cast Iron sidewalls are closed to make the machine robust and sturdy.

✅ Folding blades mounted on the carriage of steel roller chains.

✅ a simple device for quick and precise folding with knife adjustment

✅ Operating speed: 50 meters/minute.

✅ Drive on motor 2HP x 960RPM.

✅ Stroke-type length Counter with manual setting or ⭕ Digital counter.

SKU: n/a - Dyeing Machinery

Top Tube Soft Flow

Top Tube Soft flow dyeing machine very much suitable to process delicate woven & knitted fabrics. It’s soft nozzle decrease tension further avoid problems like crease marks, rope marks, shrinking etc.

Another benefit of this machine is its single vessel two chamber design reduce fabric loop length as well as processing time.

[spbsm-follow-buttons]

SKU: n/a - Dyeing Machinery

Regular Jet

Regular Jet dyeing

This machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside this polyester dyeing machine moves solely due to the force of water.

It is user-friendly because, If we compare it with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 LBest Polyester dyeing machine with a low liquor ratio in a Jet dyeing form.

SKU: D/JD-1 - Dyeing Machinery

Hydraulic Jigger

Hydraulic Jigger

Hydraulic Jigger is a piece of revolutionary equipment for open-width Scouring, Bleaching & Dyeing processes in batch form. One of the best Dyeing machinery with perfect dyeing results. Hydraulic Jigger has the following features:

- Firstly, Hydraulic Jigger’s Adjustable tension according to Fabric quality ensures perfect pre-treatment and dyeing irrespective of run lengths for the same shade/colour. In other words, Hydraulic Jigger dyes the Clothing rapidly with accuracy.

- Secondly, Hydraulic Jigger comes with closed chambers with doors that close while the operation is performing. Which gives it desired temperature in less time. Therefore, less wastage of resources.

- Thirdly, Consistent dyeing of the same shade for any number of times in the future, Moreover the highly efficient washing system saves washing time and precious Water. The uniform tension, process time, and ideal temperature contribute to the dying quality.

- Fourthly, Hydraulic Jigger controls these parameters resulting in fully controllable and reproducible shades. The controlled temperature and a steady circulation of dye liquid for flawless dyeing. PLC aided operation for repeatability. Suiting, shirting, and delicate fabrics such as rayon are best suited.

- Fifthly, the Hydraulic Jigger is available in 500kg and 1000kg capacity from 1200mm to 3000mm working width depending on the client’s need. Fabric ranging from 70 to 700 gsm/meter square of woven material may be dyed in a Hydraulic Jigger, making it ideal for Suiting, Shirting, and Delicate textile such as rayon.

Above all, flawless synchronisation of linear speed results in tension-free and crease-free fabric conveyance throughout the process.

🔸 Technical Specification

➡ Automatic reversal at the end of each cycle setting

➡ Spray washing through a selector switch

➡ Stopping the machine at the pre-determined sampling point

➡ Water filling through rotary switch

➡ Drain through a selector switch

➡ Digital Speed indication

➡ Speed setting through P L C

➡ Replenishing from dosing tank through valve

➡ Indirect steam heating through Heat Exchanger

➡ Temperature Controller.

➡ A valve adjusts the tension on the cloth.

➡ Soft Start & Stop

➡ Pendulation when adding and emptying liquid

➡ Touch Screen

➡ Specially designed software for the machineSKU: D/HJ-1 - Washing Machinery

Open Width Washing Range

Open width Washing Range

Open width Washing Range is for the fabric washing machine for woven fabrics. The Open width Washing Range machine has the following features.

- Firstly, The system consists of a specially shaped impeller in the drum in which water jets uniformly smashes the full fabric width very high washing performance on the upper and backside of the fabric.

- In other words, Open width Washing Range removes unfixed dyestuff, gum, and other chemicals from the fabric.

- Secondly, Washing with tanks can carry out pre-washing, rinsing, and chemical treatment.

- Therefore, Open width Washing Range improves fabric quality.

- An effective squeezer between the washing unit gives maximum liquor separation from one bath to another.

- Thirdly, Each washing compartment with its force-spray system, re-circulation pump, filtering device, overflow, drain, and heating arrangement.

- Fourthly, the Open width Washing Range’s working width is to be made from 1500mm to 3500mm depending on the client’s need.

- Fifthly, ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabric can be processed on this machine.

- Sixth and most Important is Perfect synchronizing of linear speed hence tension-less and creaseless transport of fabric all along the process.

🔶 ADVANTAGES :

✅ Excellent Washing efficiency.

✅ Extremely sturdy construction.

✅ Quiet running.

✅ Low energy consumption.

✅ Ease of operation.

✅ Optional knife spray between each strand of fabric with supply from a separate pump.

✅ Circulation and counter flow arrangement to save water.

✅ Low maintenance.

✅ Quick and simple installation.

✅ Tight closing glass windows on the sides to provide easy access.

✅ Direct steam heating by perforated S S Pipes.

✅ S S bottom rolls running in self-aligning bush bearing.

SKU: n/a

There are no reviews yet.