Fabric Inspection Fold/Batch

Is to be use for multiple applications, In this Fabric Inspection fold/batch machine there are following features in it.

- Firstly, it does inspection of the fabric to know if there any fault are there in fabric or to understand nature of it which came in factory for dyeing/printing/processing operations.

In other words, fabric is need to be check before starting any processes on it - Secondly, it roll fabric on batching trolley from fold/loose form by pressure roll assisted with twin – Pneumatic Cylinders, AC Motor & Gearbox..

- Thirdly, batching capacity depends on batching trolley’s capacity to load or as per need.

- Fourthly, Machine working width can be made from 1000mm to 3500mm depending on client’s need.

- Fifthly, Fabric ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester can be roll on this machine.

- Sixth and most importantly the speed can be achieve up to 30 meters per minute while preforming the process.

In conclusion, this machine is best suitable for garment industry or dyeing & printing units.

₹351,000.00

CompareFabric Inspection Fold/Batch

Is to be use for multiple applications, In this Fabric Inspection fold/batch machine there are following features in it.

- Firstly, it does inspection of the fabric to know if there any fault are there in fabric or to understand nature of it which came in factory for dyeing/printing/processing operations.

In other words, fabric is need to be check before starting any processes on it - Secondly, it roll fabric on batching trolley from fold/loose form by pressure roll assisted with twin – Pneumatic Cylinders, AC Motor & Gearbox..

- Thirdly, batching capacity depends on batching trolley’s capacity to load or as per need.

- Fourthly, Machine working width can be made from 1000mm to 3500mm depending on client’s need.

- Fifthly, Fabric ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester can be roll on this machine.

- Sixth and most importantly the speed can be achieve up to 30 meters per minute while preforming the process.

In conclusion, this machine is best suitable for garment industry or dyeing & printing plants.

Technical Specification

- Speed : 0 to 30meters/minute.

- Speed variation by A.C. Inverter.

- Reverse – Stop – Forward Arrangement through A. C. Inverter.

- Unwinding by means of Pressure Roll assisted with Twin – Pneumatic Cylinders, AC Motor & Gearbox.

- 3″ Dia Guide Rollers.

- Revolution type Meter Counter.

- Winding & Unwinding both on opposite side.

- Transparent and Inclined Inspection Table with Top and Bottom illumination.

- Strong built closed side Frames to withstand and width and weight of the fabric.

- Cloth Inspection & Winding Unit are completely wired electrically, only main supply is to be provided.

Payment, Taxes and Delivery

Payment: 50% Advance online & Balance against Proforma Invoice prior to dispatch.

Delivery: Delivery of machine is ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% Or Vat 4% +1% No CST against form “H”( export orders).

Erection: Will be charged extra per machine over and above given price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

| Fabric Width | 1000 mm, 1100 mm, 1200 mm, 1300 mm, 1400 mm, 1500 mm, 1600 mm, 1700 mm, 1800 mm, 1900 mm, 2000 mm, 2100 mm, 2200 mm, 2300 mm, 2400 mm, 2500 mm, 2600 mm, 2700 mm, 2800 mm, 2900 mm, 3000 mm, 3100 mm, 3200 mm, 3300 mm, 3400 mm, 3500 mm |

|---|---|

| Maximum Roll Size | 100 mm, 200 mm, 300 mm, 400 mm, 500 mm, 600 mm, 700 mm, 800 mm, 900 mm, 1000 mm |

Based on 0 reviews

Be the first to review “Fabric Inspection Fold/Batch”

-

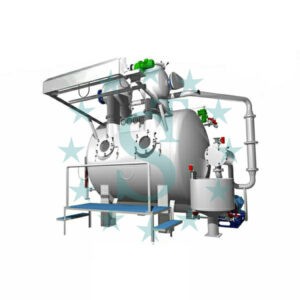

Dyeing Machinery

Hydraulic Jigger

Hydraulic Jigger

Hydraulic Jigger is a piece of revolutionary equipment for open-width Scouring, Bleaching & Dyeing processes in batch form. One of the best Dyeing machinery with perfect dyeing results. Hydraulic Jigger has the following features:

- Firstly, Hydraulic Jigger’s Adjustable tension according to Fabric quality ensures perfect pre-treatment and dyeing irrespective of run lengths for the same shade/colour. In other words, Hydraulic Jigger dyes the Clothing rapidly with accuracy.

- Secondly, Hydraulic Jigger comes with closed chambers with doors that close while the operation is performing. Which gives it desired temperature in less time. Therefore, less wastage of resources.

- Thirdly, Consistent dyeing of the same shade for any number of times in the future, Moreover the highly efficient washing system saves washing time and precious Water. The uniform tension, process time, and ideal temperature contribute to the dying quality.

- Fourthly, Hydraulic Jigger controls these parameters resulting in fully controllable and reproducible shades. The controlled temperature and a steady circulation of dye liquid for flawless dyeing. PLC aided operation for repeatability. Suiting, shirting, and delicate fabrics such as rayon are best suited.

- Fifthly, the Hydraulic Jigger is available in 500kg and 1000kg capacity from 1200mm to 3000mm working width depending on the client’s need. Fabric ranging from 70 to 700 gsm/meter square of woven material may be dyed in a Hydraulic Jigger, making it ideal for Suiting, Shirting, and Delicate textile such as rayon.

Above all, flawless synchronisation of linear speed results in tension-free and crease-free fabric conveyance throughout the process.

🔸 Technical Specification

➡ Automatic reversal at the end of each cycle setting

➡ Spray washing through a selector switch

➡ Stopping the machine at the pre-determined sampling point

➡ Water filling through rotary switch

➡ Drain through a selector switch

➡ Digital Speed indication

➡ Speed setting through P L C

➡ Replenishing from dosing tank through valve

➡ Indirect steam heating through Heat Exchanger

➡ Temperature Controller.

➡ A valve adjusts the tension on the cloth.

➡ Soft Start & Stop

➡ Pendulation when adding and emptying liquid

➡ Touch Screen

➡ Specially designed software for the machine

SKU: n/a -

Burner, Heating Solution

Burner 550 – Stage 3

Burner 550 | Heating solution

This heating solution burner 550 comes to volume, potential, and cost efficiency. The Burner 550 is a series stage 3 covers output ranges under 80mg/kWh. These gas burners were designed with an advanced combusting head which provides consistent combustion even under difficult working conditions.

The placement of the components inside the burner permits easy and precise regulation and maintenance.

Benefits

🔥 Amazingly efficient at burning gas

🔥 Stable flame no matter what kind of weather you’re dealing with

🔥 High efficiency (80mg/kWh)

🔥 Efficient, clean combustion

🔥 Power is increased without complications✅ Easy to maintain

✅ Great energy savings

SKU: n/a -

Finishing Machinery

Stenter

The Stenter or Hot air Stenter Machine is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities give the fabric the final result of all the processes it went through.

Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out.

It also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.🔶 Efficiency

✅ Double-jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advanced chamber technology makes it easy to install and reinstall if needed without interfering with the performance.Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

SKU: S001 -

Processing Machinery

Polymeriser

Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.

SKU: P001 -

Dyeing Machinery

Top Tube Soft Flow

Top Tube Soft flow dyeing machine very much suitable to process delicate woven & knitted fabrics. It’s soft nozzle decrease tension further avoid problems like crease marks, rope marks, shrinking etc.

Another benefit of this machine is its single vessel two chamber design reduce fabric loop length as well as processing time.

SKU: n/a -

Dyeing Machinery

HT.HP. Soft Over Flow

HTHP Soft Over Flow is just like the HTHP Soft Flow machine with a bigger capacity & for heavy fabrics.

HTHP Soft Over Flow is Specially Designed to process Heavy and sensitive fabrics like Terry Towel, and Curtain Bedsheet of 100% Cotton knit and woven fabrics. In short, it’s a Terry towel dyeing machine.

HTHP Soft Over Flow can work as a Soft Overflow with minor adjustments.

A larger nozzle diameter, with a Higher volume & low-pressure nozzle design and inside Teflon sheet are helpful to move the fabric very smoothly and gently without damaging the cloth.

A specially develop online filter design helps to collect the Terry towel fumes.

🔸 Technical Specification

✅ Capacity: 50 to 2000 kg.

✅ The process has a sensitive fabric like Terry Towels, Curtain, Bed Sheet, 100% cotton knit & woven etc.

✅ Work as Soft flow or as overflow dyeing.

✅ High Temp. – Up to 140 ° C.

✅ The vessel makes of stainless steel 316 L.

✅ Specially developed a filter to collect towel fumes.

✅ Teflon Sheet inside the chamber for smooth fabric movement.

✅ High volume, Low-pressure soft nozzle with a larger diameter for heavy and Larger width fabrics

✅ Fabric drive reel with frequency controller.

SKU: D/HSO-1

There are no reviews yet.